Plastic Molding Manufacturers

Plastic processes differ greatly in both the way they form plastic products and in the shape and structural integrity of the products they manufacture. Blow molding, for example, is nearly the sole method by which plastic bottles for beverages, household cleaners and cosmetic products are made, as well as a range of low-cost toys and parts with low to medium performance.

Plastic processing methods vary significantly in how they shape and form products, impacting the final structure and integrity of the items produced. Take blow molding, for instance. This technique is almost exclusively used to create plastic bottles for beverages, household cleaners, and cosmetics. Additionally, it is used to produce a variety of low-cost toys and components with low to medium performance.

Applications

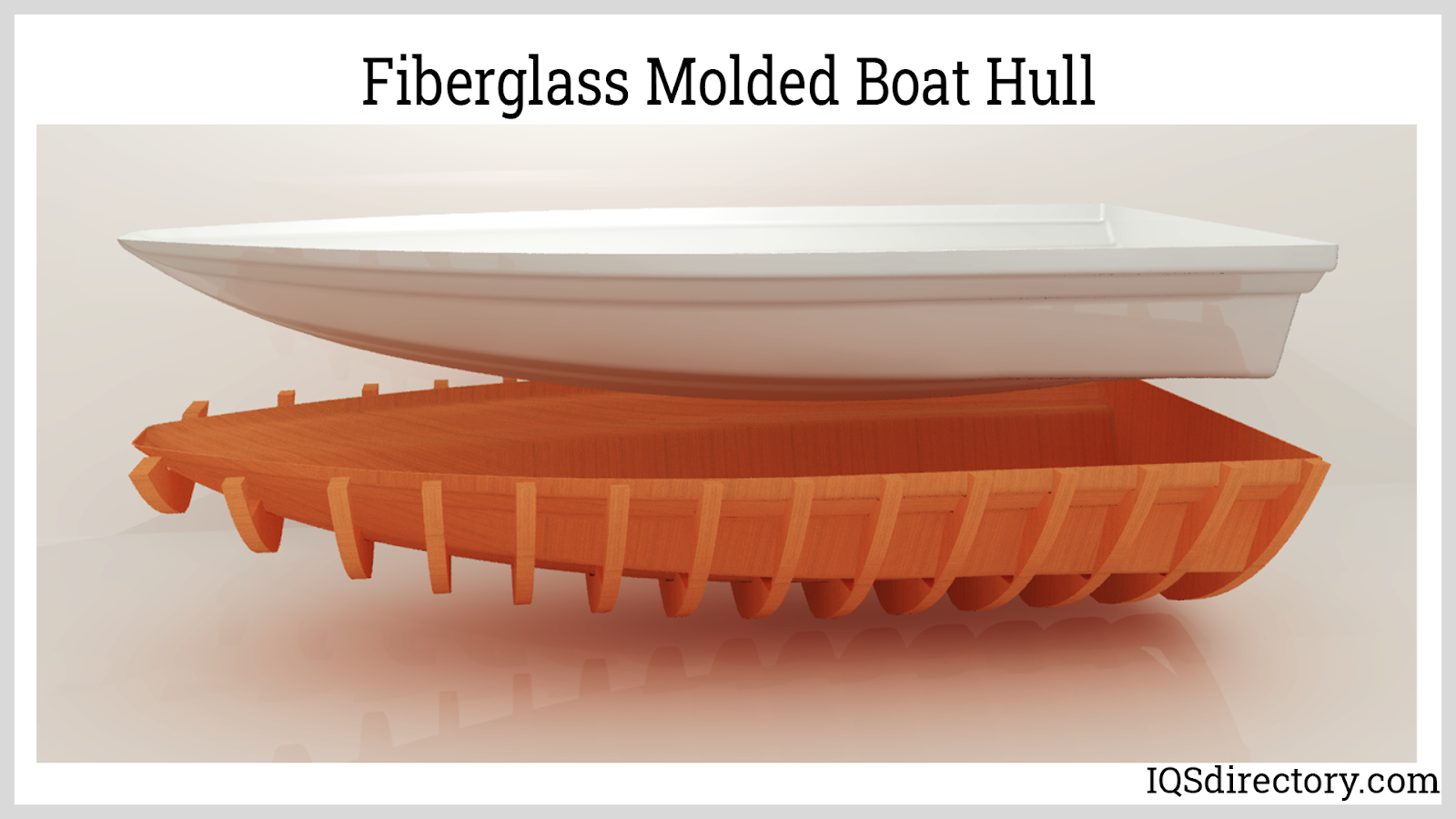

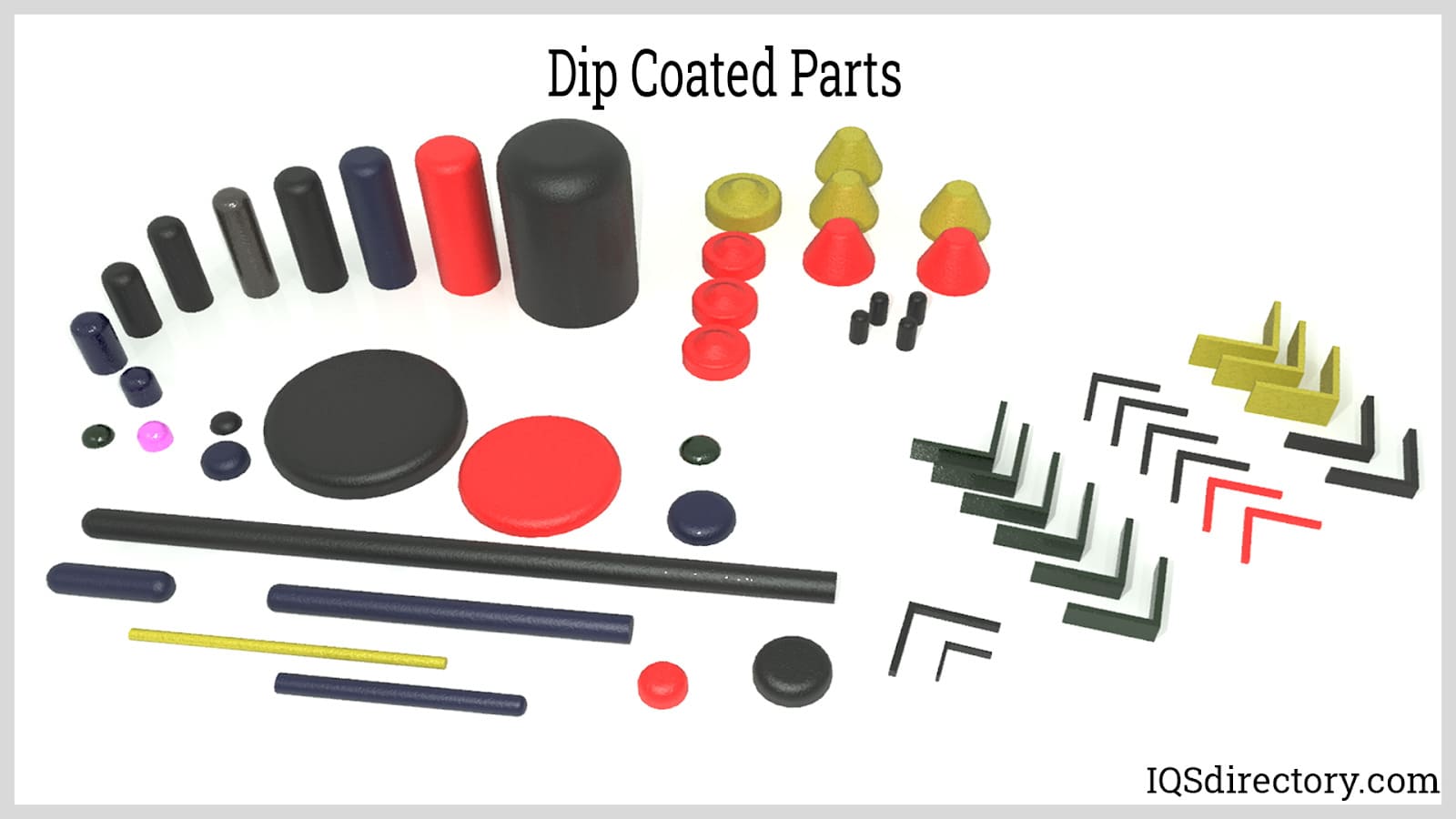

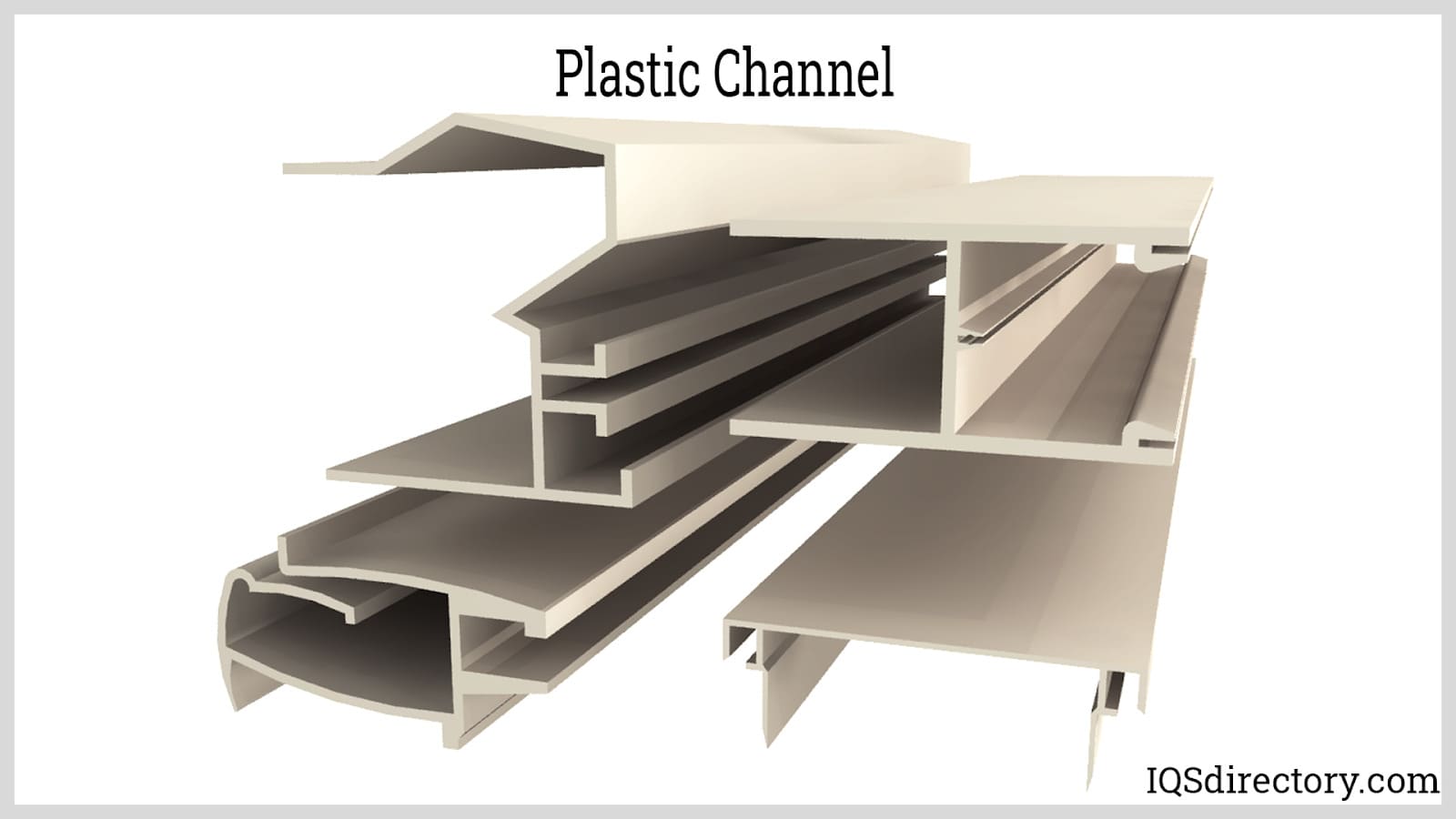

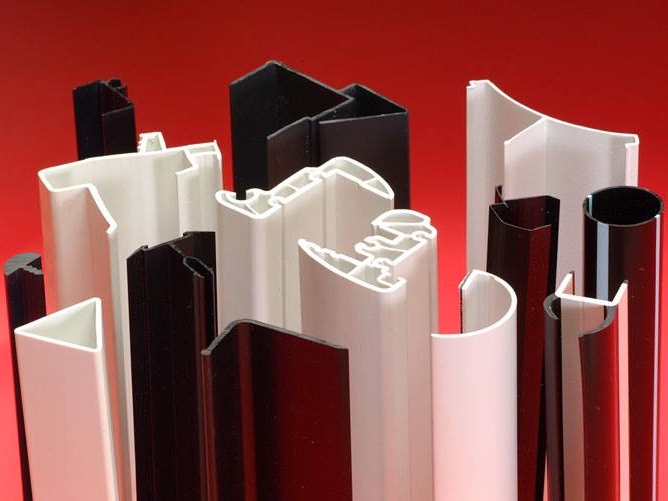

The extrusion process produces linear profiles, strips, and sheets with high structural integrity, making them suitable for construction siding, trim, and furniture applications. Vacuum forming, or thermoforming, shapes trays, linings, and thin plastic packaging from heated plastic sheets. Dip molding creates various soft molds and plastic coatings. Other molding processes utilize casts or dies: injection molding injects melted plastic resin into a closed mold to form solid plastic objects, while rotational molding uses a gyroscopic motion to evenly coat the inside of a mold, producing hollow parts with high impact resistance.

Plastic molding processes vary significantly in cost. High-end methods like rotational molding and injection molding deliver precise, three-dimensional plastic parts with exceptional structural integrity and impact resistance. Conversely, blow molding and dip molding offer cost-effective solutions for mass-producing containers and household items. Various plastic materials are used in these processes, although some methods are more suitable for specific polymers than others.

Plastic molding is the predominant manufacturing technique for everyday items such as automotive dashboards, bottle caps, and children’s toys. Plastic’s versatility makes it a preferred alternative to metals, wood, and glass. Thermoplastics, thermosets, and elastomers are popular due to their durability and malleability. This molding process is ideal for mass production and prototyping, allowing for high-volume output with precise tolerances.

Plastic molding involves using pre-made molds and liquid plastics, with methods such as vacuum forming, injection molding, blow molding, and compression molding. The choice of process depends on the product’s intended use, and these methods are prevalent in the consumer, food service, medical, plumbing, computer, and automotive industries.

The materials used in plastic molding have distinct characteristics. Thermoplastics become pliable with heat, allowing them to be melted and molded into various shapes. They can be remolded but tend to be brittle in cold temperatures. Thermosets, like melamine resin or polyimides, harden and become brittle after molding, suitable for applications requiring cold exposure but cannot be remelted and remolded.

Elastomers, such as rubber, retain their elasticity after cooling, which is essential for certain molded plastic products. They are commonly used in the production of items like children’s toys and tool handles, where elasticity enhances comfort.

Plastic molding offers several advantages, including quick turnaround times, reduced labor costs, and the ability to create complex shapes with minimal waste. Unlike materials like metal or wood, which are difficult to mold into small, intricate shapes and can generate significant waste, plastic can be easily manipulated into a vast array of forms. The minimal waste produced can be recycled through the melt and mold process, making plastic molding an environmentally responsible manufacturing choice.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotationally Molded Plastics

Rotationally Molded Plastics Vacuum Formed Plastics

Vacuum Formed Plastics Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services