Numerous products are made from blow molding. Any consumer item that has a three-dimensional shape and is hollow, such as tanks and CD cases, is manufactured using the blow molding process. Blow molded products are capable of holding a variety of substances such as herbicides, pesticides, cosmetics, and automotive oil.

Western Industries Plastic Products LLC open_in_new

Location: Winfield, KS

No matter what your blow molding needs are Western Industries is ready to assist you. We believe in thinking outside the mold and using unique methods to come up with large-part blow molding solutions for our customers. We have access to state-of-the-art technology and over 100 years of combined experience serving a variety of industries. When you choose Western Industries, you have the Western Advantage. Call today for more information!

Lerner Molded Plastics open_in_new

Location: Aurora, OH

At Lerner Molded Plastics, we specialize in crafting high-quality blow molded products tailored to meet the diverse needs of our clients. With years of expertise in the industry, we take pride in our ability to deliver innovative solutions that exceed expectations.. For more information about our capabilities, contact us today!

Iceberg Molding open_in_new

Location: Sturgis, MI

With blow molding presses from 1 to 80 lbs., Iceberg Molding has the ability & resources for every step of your blow molding requirements - from a competitive part quote to part & product development support start to finish. Iceberg Molding has an established infrastructure like no other. We can simply mold parts for you or completely assemble & ship your finished products anywhere in the world.

Hi-Rel Plastics & Molding open_in_new

Location: Riverside, CA

Founded in 1984, Hi-Rel Plastics & Molding, Inc. is a turn-key manufacturer who offers custom blow molding and custom plastic injection molding for a variety of industries. With more than 35 years of experience, our quality products are unparalleled. We process an almost infinite variety of thermoplastic resins, our prices are competitive, our delivery is on time, and we offer superior customer service. Our company is ISO 9001:2015, AS 9100 Rev D, 13485:2016 Certified.

Valencia Plastics open_in_new

Location: Valencia, CA

Valencia Plastics is a leading edge blow molder with new methods to add value & ensure superior quality for any job from 10 grams to 3 lbs. Discover our expertise with many plastics & a wide range of machinery. Customers can expect the best from concept to end blow molded plastic product. Industries we serve include aerospace, defense, medical, commercial & pharmaceutical.

SPI Blow Molding LLC open_in_new

Location: Coloma, MI

Since 1952, SPI Blow Molding has provided custom blow molding for a diverse range of industries, such as agricultural, plumbing, electronics, and more. Our team can meet your needs with a variety of plastics, such as HDPE, ABS, polycarbonate, and TPE. Secondary operations and assembly services are also available. SPI is a leader in our industry due to our customer-oriented ability to deliver successful production solutions and unmatched product quality.

EXI-plast Custom Moulding Ltd. open_in_new

Location: Centralia, ON

EXI-plast is a full-service provider of custom plastic moulding services, specializing in blow moulded solutions for customers worldwide across a wide variety of industries. With over 30 years of experience developing, producing, and finishing custom plastic products, we have also become a sustainability leader through the integration of postconsumer resins. With products ranging from less than 1lb up to 30lbs, EXI-plast is Molding the Future!

The plastic utilized for these processes are all thermoplastic resins. They include acetal, polysulfone, polyamide, polystyrene, butadiene styrene, Barex, polyvinyl chrloride (PVC), and high and low density polycarbonate.

Plastic blow molding can be categorized into three types: injection blow molding, extrusion blow molding, and stretch blow molding. All of these processes consist of two steps, which vary the most in the early stages. The ultimate shape of the blow molded plastic depends on the shape of the mold cavity. While blow molded products come in an assortment of standard shapes and sizes, there are some products that can be made using custom blow molding, and are thus used for special applications.

Plastic blow molding is widely used because it is well-suited for the manufacturing of durable hollow parts and because it can be used to form standard and common plastic shapes, but also can be custom designed to create plastic products that are specific to a customer’s unique needs.

Plastic blow molding is widely used because it is well-suited for the manufacturing of durable hollow parts and because it can be used to form standard and common plastic shapes, but also can be custom designed to create plastic products that are specific to a customer’s unique needs.

While injection molding and rotational molding are more precise methods of plastic molding, plastic blow molding offers the advantage of high-volume capacity, fast turnaround times and relatively low costs. The process usually takes a matter of seconds and therefore blow molding machines can produce high-volumes of durable plastic products in short periods of time with minimal finishing requirements.

In the basic process of plastic blow molding, plastic is melted and softened and formed into a parison which is then clamped into a mold. A blow pin is then used to force compressed air into the parison, and the molten plastic expands to fit the shape of the cavity. Controlled and constant air flow is essential to the quality of the final outcome as varying wall thicknesses compromise the strength and durability of the product.

Blow molders have to ensure the constant expansion of the plastic in the mold to achieve uniform wall thickness in the product. The cavity is then cooled, usually by conduction, and the hardened plastic product is removed from the mold, sometimes with the assistance of ejector pins. There are three main processes of plastic blow molding: injection, extrusion and stretch. Injection blow molding is a combination of standard injection molding methods and plastic blow molding and is typically used to create smaller products that require greater precision.

Extrusion molding allows for a wide variety of shapes and sizes, with the added benefit of handleware capabilities, and yet results in a thin seam where the two mirror parts of the cavity joined. Stretch molding is commonly used to produce vast quantities of plastic bottles.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

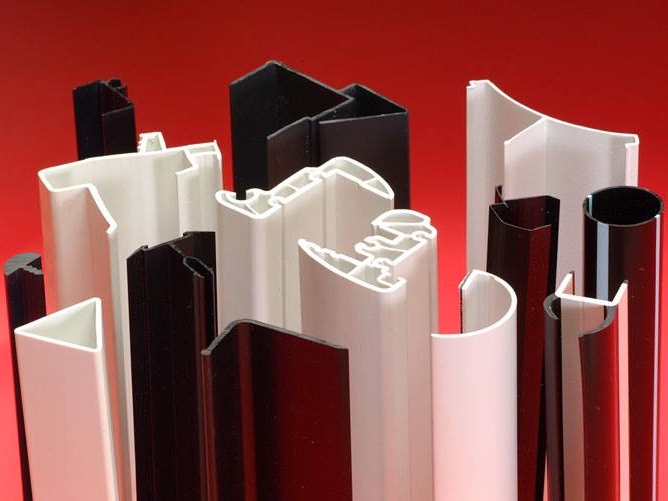

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotationally Molded Plastics

Rotationally Molded Plastics Vacuum Formed Plastics

Vacuum Formed Plastics Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services