Polyurethane urethane molding is the process used to create molded urethane parts (molded polyurethane parts). This process is used by manufacturers to fabricate a wide variety of parts and products for an equally wide range of industries, such as: athletic equipment, engineering, manufacturing, industrial, food processing, automotive, and construction. Read More...

TPC, Inc. open_in_new

Location: Fontana, CA

TPC, Inc. is a leader in the polyurethane molding industry. Our state-of-the-art manufacturing facilities focus on providing high-quality products, competitive pricing, and exceptional customer service. Our team of experts is dedicated to the production and innovation of our products. As a result, TPC, Inc.’s custom-fit solutions are perfected for customers of all industries.

Weaver Industries, Inc. open_in_new

Location: Denver, PA

From concept, to production, to delivery, we have over 40 years experience with made-to-order cast urethane & cast polyurethane elastomer products. Weaver Industries offers urethane wheels, polyurethane molding, molded urethane, urethane sheets, & urethane/polyurethane manufacturing. Skilled at custom casting, discover the advantages of our urethane sheet and Action Mallet heads.

FallLine Corporation open_in_new

Location: Reno, NV

FallLine has been a manufacturer of custom polyurethane molding products for various industries since 1981. We offer a wide range of proven materials ranging from 40A - 80D, as well as the capability to formulate materials to meet specific needs. Our knowledgeable staff, on-site design team and machine shop are dedicated to offering excellent customer service and rapid turnaround times.

Uniflex Inc. open_in_new

Location: Brighton, MI

Since 1979, Uniflex has been a leading manufacturer of urethane products. We provide high-quality urethane rollers and urethane castings, as well as urethane molded products available in an array of colors. Uniflex offers customized body blocks and engine components for the automotive industry. Our team is dedicated to advancing our company and raising industry standards.

Dynatect Ro-Lab, Inc. open_in_new

Location: Tracy, CA

At Dynatect Ro-Lab, Inc., we take pride in our expertise and specialization in polyurethane molding, offering unparalleled solutions for a myriad of applications. With our advanced capabilities, we excel in bonding urethane to diverse metal sub-surfaces, including aluminum, brass, and steel. As a team, we understand the unique demands of various industries, and our commitment to quality is reflected in our ability to seamlessly integrate polyurethane with a wide variety of metal substrates.

Polyurethane moldings have an excellent reputation for their high performance, which is why they are so popular. Their longevity is greater than that of plastic, and they are more impact, abrasion, radiation, cold flow and low temperature resistant than rubber. They also have elastic memory, reduce noise, and resist to heat and chemicals. They possess many of the good qualities of metal, rubber, and plastics, and they are capable of forming strong adhesive bonds with most plastics and metals. Compared to most rubber materials, polyurethane has a higher resistance to petrochemicals. Polyurethane can be effectively used in casting; cast polyurethane works well with low pressure tooling and thick section molding.

Products Produced

This process is used by manufacturers to fabricate a wide array of moldings, parts, bowling balls, urethane bumpers, polyurethane belts, conveyor bushings, electrical potting compounds, press tool blocks, and pneumatic seals. It is especially valued for its uses in “memory foam” products. For a more in-depth look at molded polyurethane products, we can break them down into groups by industry.

Automotive Products

Examples of molded urethane automotive products include: automobile seats and seat belts. While upholstered with another material, the substantial, cushion-y seat is made from injection molded urethane. In addition, polyurethane can be used for applications such as tires for trucks, due to how well it can handle compression loading.

Recreational Products

Examples of recreational products produced through urethane molding include: surfboards, skateboard tires, inflatable boats and high-end tennis racquet grips. Surfboards feature solid molded urethane cores, which make them light and durable. Molded urethane tires make it easier for a skateboarder to perform difficult tricks. Inflatable boats feature components made from urethane sheets. Tennis racquet grips made from molded urethane are highly stretchable, so that can create a tight, glove-like grip.

Machine Products

Molded polyurethane machine parts include conveyor wheels and urethane bushings. Molded urethane conveyor wheels, while more expensive than rubber conveyor wheels, are more abrasion resistant and durable than rubber wheels. Molded urethane bushings are quickly replacing rubber bushings because they hold up in situations where rubber bushings fail or wear out quickly, like: salty environments, chemical environments, high abrasion applications and oil saturated situations. In addition, urethane bushings are better at maintaining correct wheel alignment.

Electronic Products

Molded urethane works as an excellent outer shell to electronic components of all kinds. They shield them from abrasion, mechanical stress, environmental stress and impact. Molded urethane electronic shields are effective up to 250℉.

History

Polyurethanes (PU) were first developed in 1937 by Dr. Otto Bayer and his coworkers. Finding that polyurethanes offered advantages over existing plastics, Bayer and his associates first focused on producing PU fibers and flexible foams. The use of polyurethanes quickly spread. Their first widespread application was aircraft coating during World War II. Other WWII applications included other coatings and resistant clothing.

Mass production of polyurethane foam, gum rubber and elastomers began in 1954, using toluene diisocyanate (TDI) and polyester polyols. By the late 1950s, manufacturers were producing flexible cushioning foams.

During the 1960s, automotive engineers adapted one of the most common molded urethane applications we know today—automotive interior components. The first of these were safety components, like instrument and door panels. These were produced by backfilling thermoplastic skins with semi-rigid urethane foam. In 1969, Bayer (the company) presented an all-plastic car in Düsseldorf, Germany that featured certain components, like the body panels, using reaction injection molding (RIM). This was a new process that allowed them to mix urethane and reactants and then inject them into a mold for shaping. From the RIM process was soon developed reinforced RIM (RRIM), an injection molding process in which they created reinforced products with added filler (Mica, processed mineral fibers, milled glass, etc.). This process offered manufacturers added product stiffness, better thermal stability and less thermal expansion. Using RRIM, automotive manufacturers built the first American plastic-body automobile, the Pontiac Fiero, in 1983.

That same decade, automotive engineers replaced PVC plastisol with water-blown microcellular flexible PU foams for molding panel gaskets and air seal filters. They also developed yet another RIM process, structural RIM, also known as resin injection molding. This process involved placing glass mats into the RIM mold cavity. This allowed manufacturers to create even stiffer products.

Today, molded urethane manufacturers create products for all sorts of applications and industries. Because they have developed even more urethane varieties, they can withstand a greater variety of temperatures and environments.

Materials Process

Polyurethane

The material referred to in “molded urethane” is polyurethane. Polyurethane is, generally speaking, a polymer made up of organic units joined by carbamate (urethane) links. There are many different types of polyurethane. However, most polyurethanes share the qualities of flexibility and rigidity.

Raw Polyurethane

Raw polyurethane materials exist in a liquid state, as far as castable urethane is concerned. Because of this liquid state, the raw material can be easily measured and mixed and prepared for molds.

Sulfur

Sulfur is a slow vulcanizing agent, and is often used alongside other materials to improve the final product’s stability.

Process Details

1. Mold Formation

In preparation for the main polyurethane molding process, manufacturers develop a silicone rubber mold (sometimes erroneously called “silicon rubber”) and a master pattern.

2. Pre-Polymer Formation

Once they make the mold, manufacturers mix the raw polyurethane materials so that they react and form a pre-polymer solution.

3. Polymeric Transition

During the urethane molding process, the polymeric transition is completed when a curative is mixed with the pre-polymer solution.

4. Pouring

The mixture is then accelerated by pressure or heat as it is poured into a mold cavity. In this stage, coloration and other chemicals may be added for aesthetic purposes.

5. Curing

Finally, the mixture cools, hardens and cures to form the final polymer product.

Design

When designing a molded urethane part, manufacturers think about application specifications, such as: product shape, product thickness, required product characteristics (abrasion resistance, corrosion resistance, etc.), product size, product volume and standard requirements.

To create a custom urethane molding for you, they can do a number of things. First, they can create a custom mold. A custom mold will ensure that your part comes out shaped and sized just how you want it. Second, they can alter your material. If your product will be made from foam, for example, they can alter it to act as rigid foam, semi-rigid foam or flexible foam. They can also put in additives that change coloring. Finally, they can engage in any number of secondary operations to create custom characteristics, like special coatings, labeling, etc. For more information of custom product design, discuss your specifications with your prospective manufacturer.

Variations and Similar Processes

The two main types of urethane molding are open urethane casting and closed urethane casting. Other types include: polyurethane foam molding, room temperature vulcanization (RTV), reaction injection molding (RIM) and

Open Urethane Casting

During the process of open polyurethane molding, the pre-polymer and curative are heated and mixed. Next, the mixture is poured into an open mold cavity. There, the cast urethane is cured. In this case, the curing process does not involve the application of pressure.

Closed Urethane Casting

Closed polyurethane molding processes, such as injection molding, involve heating the curative and pre-polymer, mixing it together, and injecting it through small holes into a closed mold cavity. Inside the mold, with the help of heat and pressure, the cast urethane cures.

Polyurethane Foam Molding

Polyurethane foam molding is a foam molding process which is frequently used by manufacturers to make soundproofing insulation. The final product is an excellent coefficient of friction, and possesses exceptional, flexibility, compression, and tension properties. Furthermore, foam urethane products are highly stable, enabling them to maintain their hardness over their entire operating lifespan.

Room Temperature Vulcanization (RTV)

The polyurethane molding process is actually a subset of RTV. RTV often involves using materials such as polyurethanes, silicone, or wax. This process has a few benefits, including the ability to achieve an excellent surface finish and a high level of detail. Polyurethane is a popular material for this process because of its hardness and its ability to withstand temperatures up to 220F (approx. 104C). The rapid manufacturing and prototyping chemical process of RTV involves adding curatives such as sulfur in an effort to convert materials such as polyurethane into a compound that is much more durable.

The RTV process is ideal in projects in which the manufacturer requires a short run of parts that must be similar in physical appearance or functional capabilities compared to parts or materials that have been previously produced.

Reaction Injection Molding (RIM)

During RIM, manufacturers mix liquid polyisocyanate with liquid additives (blowing agents, surfactants, catalysts, polyols, etc.), which they then inject into molds. While the urethane mixture is in the mold, it is exposed to high pressure via an impinging mixer and cured. RIM molding offers the advantages of lower tooling costs and strong and lightweight products. However, its raw materials are more expensive than other methods and it requires a higher cycle time per product.

Injection Molding

Urethane injection molding is very similar to regular plastic injection molding. The main difference is that, instead of a liquid material, it uses thermoplastic polyurethane pellets. The pellets are placed inside a screw column where, put under high pressure and temperatures, they turn into liquid. Once liquid, the material is injected into the mold. Urethane injection molding produces high tolerance parts at high volumes. However, sometimes these products can come out low quality, with knit lines. In addition, tooling is very expensive.

Compression Molding

Finally, compression molding involves using a heated mold. Manufacturers place the polyurethane inside the mold, where pressure forces the urethane to spread out and shape, then cure. Compression molding creates products with large cross sections and it can eliminate the need for secondary processing. It can, however, be expensive as well.

Benefits

Cost Effectiveness

Polyurethane molding offers lower cost tooling. Overall, it costs roughly the same as polymer molding and rubber molding.

Quality

In addition, the polyurethane molding process is capable of forming parts without drafts or with undercuts. It is highly precise, is capable of working with a wide range of part sizes.

Efficiency

Urethane molding has a fast turnaround time. Polyurethane molded parts require little to no additional finishing.

Material Superiority

Polyurethane elastomers have several laboratory-tested advantages compared to elastomers made from different materials. Polyurethane is highly resistant to radiation, ozone, oxygen, oxidation oil, tear, cut, and abrasion. Additionally, it has a greater load bearing capacity, a broader range of hardness, and is easier to color than rubber. Urethane has also been proven to resist wear and tear more effectively than some types of steel. Compared to metal, polyurethane is more resilient and more capable of reducing noise. It is highly flexible, inexpensive to fabricate, and is highly resistant to impact, corrosion, and abrasion. Polyurethane is light in weight, non-conductive, easy to mold, and doesn’t generate sparks.

Things to Consider

If you’re in the market for molded urethane products, it’s important that you work with a reputable supplier that will understand your application needs. To find the right molded urethane provider for you, start by checking out those high-quality companies that have listed on this page. You’ll find them sandwiched in between information sections, complete with profiles and contact info. As you look through them, keep an eye out for manufacturers that offer services and products that may fit the bill. Also check out their delivery options and standard certification options, if available online. Pick out three or four to who you’d like to speak directly, and call or request a quote from each. During each conversation, discuss your specifications at length, as well as your budget, ideal timeline and delivery preferences. Make sure that if you require any certifications or safety standard adherences, they can meet get or meet those for you. Once you spoken with each contract manufacturer, compare and contrast their answers. Choose the manufacturer you believe will best serve your needs, and get to work.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

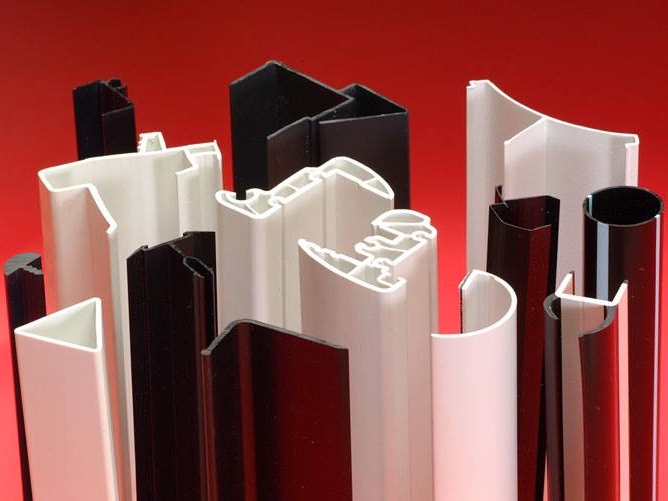

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotationally Molded Plastics

Rotationally Molded Plastics Vacuum Formed Plastics

Vacuum Formed Plastics Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services