Gordy Plastics

Gordy PlasticsRequest A Quote

Milton-Freewater, ORAt Gordy Plastics, we specialize in providing comprehensive solutions for injection molded plastics tailored to meet the diverse needs of our valued clientele. With decades of experience and expertise in the plastics manufacturing industry, we have established ourselves as a trusted leader known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a wide range of injection molded plastic components, including parts for automotive, electronics, consumer goods, medical devices, and more. We utilize state-of-the-art injection molding equipment, advanced tooling, and high-quality resins to produce precision-engineered parts with tight tolerances, complex geometries, and superior surface finishes. In addition to our premium injection molded plastic products, we offer a comprehensive suite of services to support our clients throughout every stage of their projects. Our services include engineering consultation, design assistance, prototyping, mold design and fabrication, injection molding production, secondary operations, assembly, and packaging. Our team of experienced engineers, mold makers, and production specialists collaborates closely with clients to ensure that each plastic component meets their unique needs and specifications. We invest in research and development initiatives, process optimization, and training programs to stay at the forefront of injection molding technology. This dedication to innovation enables us to provide cost-effective solutions that optimize efficiency, quality, and lead times for our clients. At Gordy Plastics, customer satisfaction is our top priority. We strive to build long-lasting relationships with our clients based on trust, integrity, and mutual success. Whether you require standard injection molded plastic components or custom-designed parts, you can rely on us to deliver high-quality products and exceptional services that meet your specific needs and exceed your expectations.

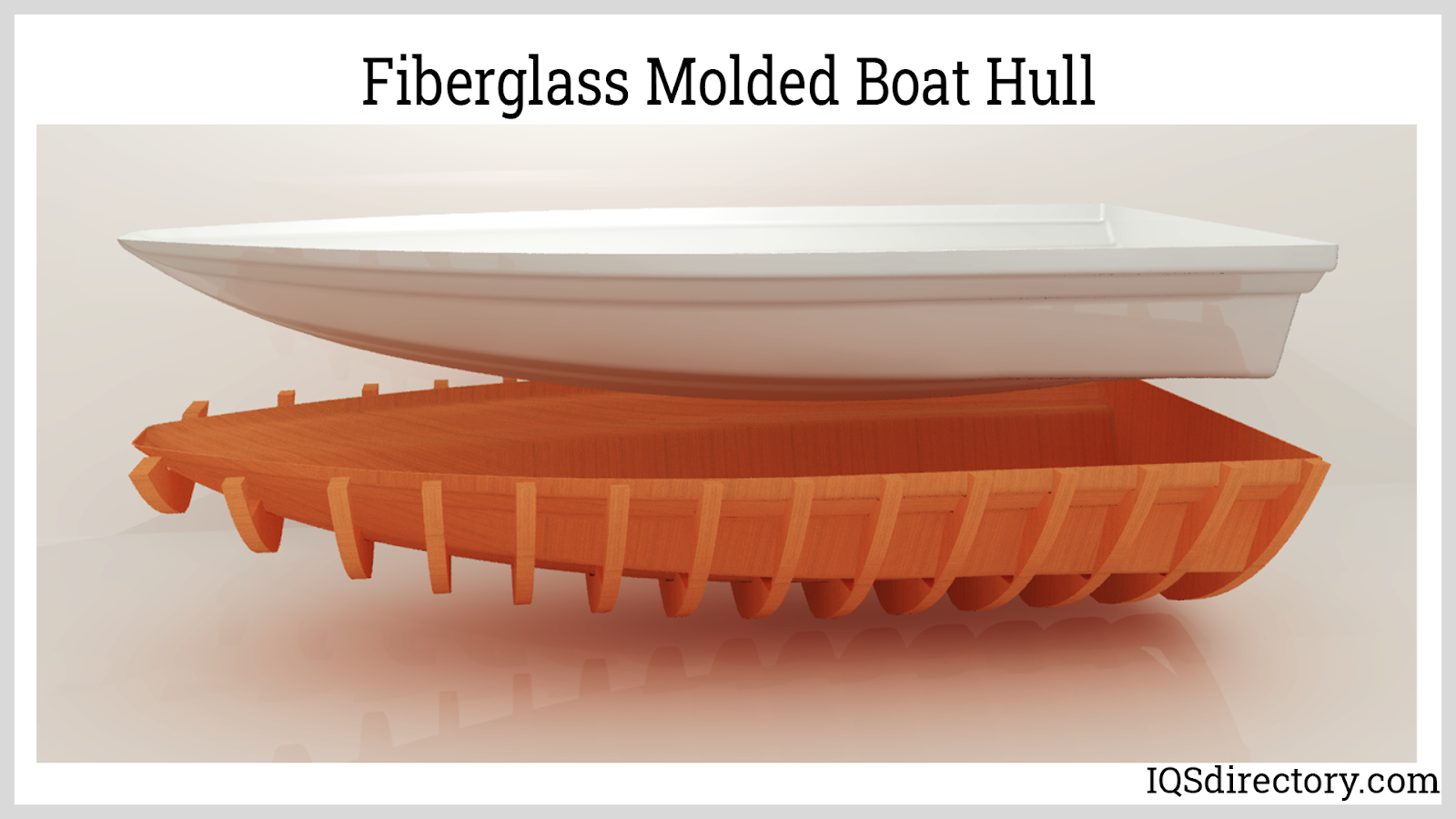

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

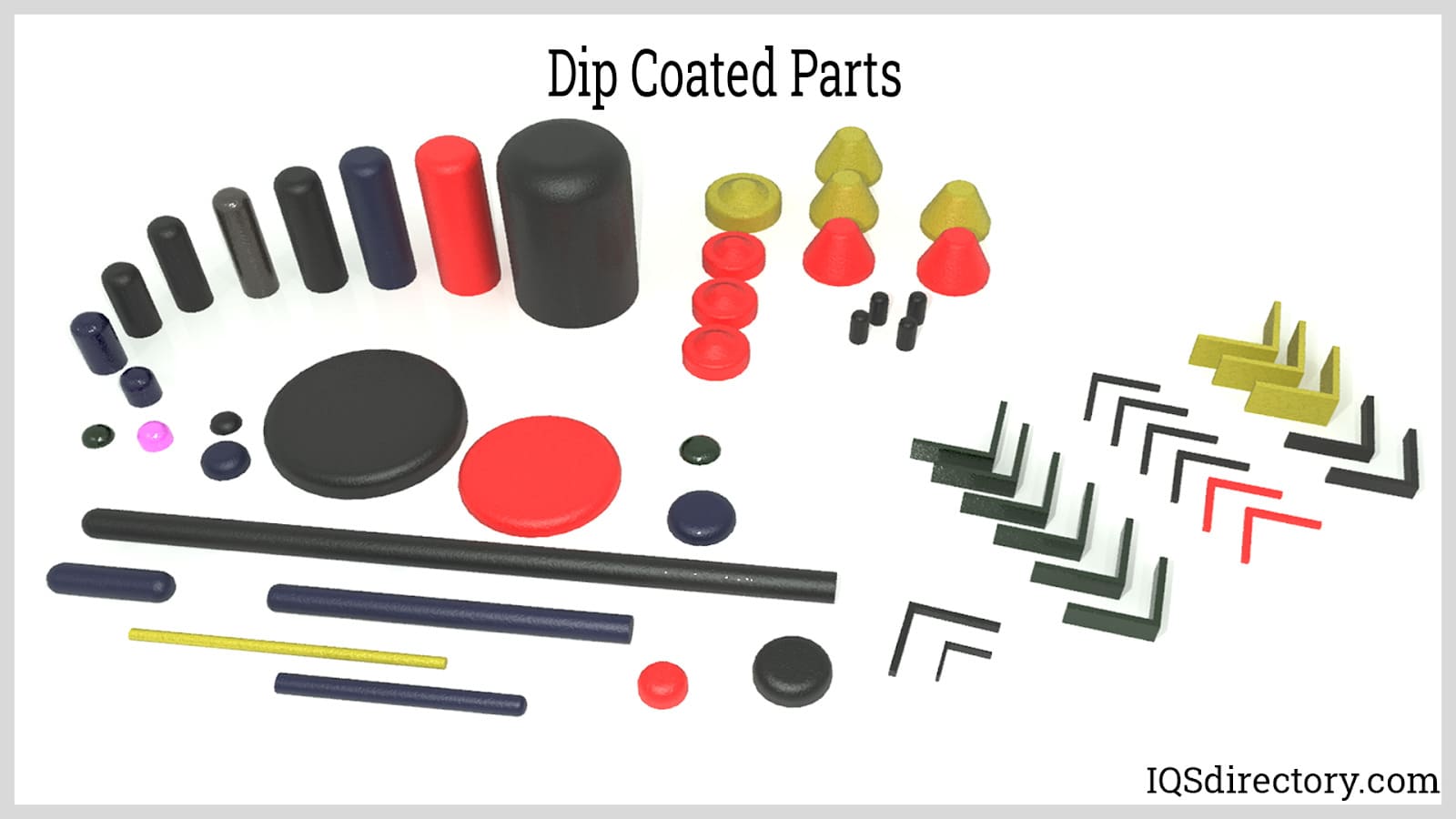

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

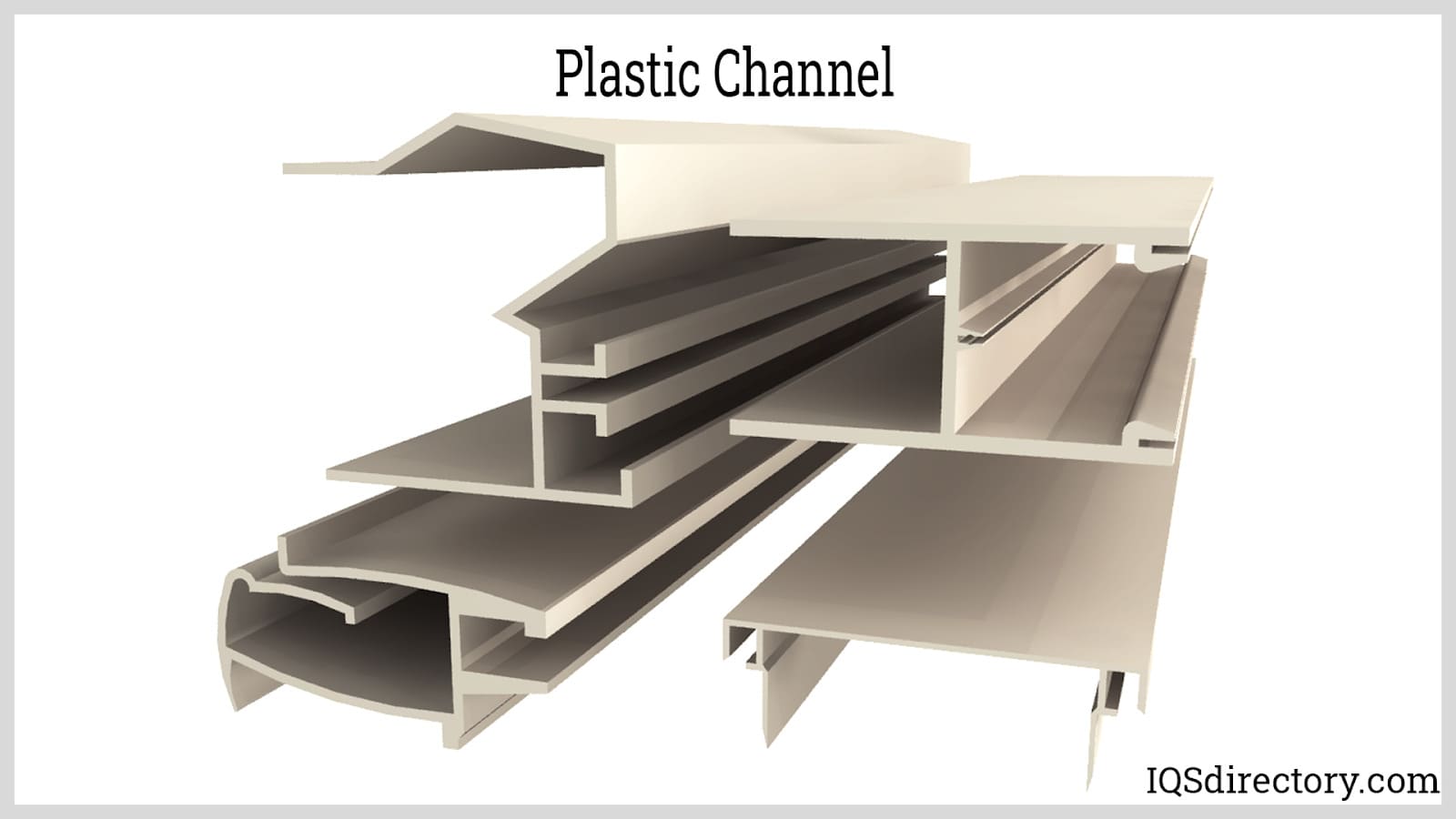

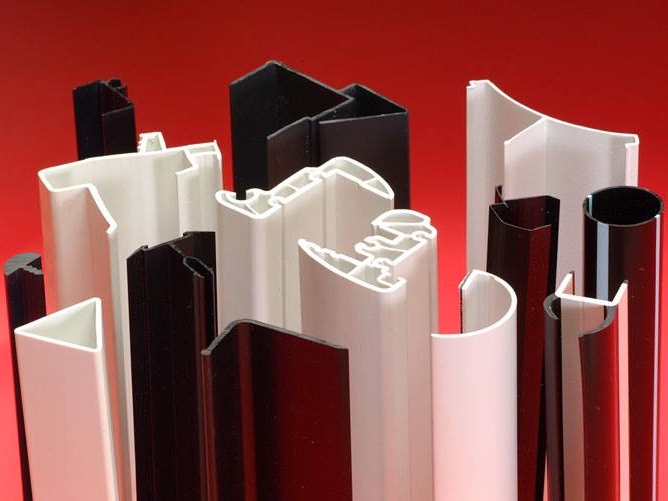

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotationally Molded Plastics

Rotationally Molded Plastics Vacuum Formed Plastics

Vacuum Formed Plastics Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services