LTM Plastics

LTM PlasticsRequest A Quote

Devner, CO | 303-592-9548We, as representatives of LTM Plastics, are proud to introduce our company, which has been specializing in injection molded plastics since our founding in 1977. Over the years, we have developed a strong reputation for delivering high-quality products and excellent customer service. At LTM Plastics, we offer a wide range of injection molded plastic products, including parts for the automotive, aerospace, medical, and consumer goods industries. Our products range from small, intricate components to large, complex assemblies. We use a variety of materials, including high-performance polymers and engineering resins, to produce parts that meet our customers' specifications. In addition to manufacturing plastic parts, we also offer a range of services to support our customers' needs. Our services include design and engineering support, prototyping, mold-making, and production. We work closely with our customers throughout the entire process to ensure that their requirements are met and that the final product meets their expectations. At LTM Plastics, we pride ourselves on our advanced capabilities in injection molding. Our state-of-the-art facility is equipped with the latest technology, including advanced robotics, automation, and quality control systems. We have a team of highly skilled technicians and engineers who are experienced in working with a wide range of materials and processes. This allows us to offer our customers a wide range of capabilities, including multi-shot molding, insert molding, and overmolding. In summary, LTM Plastics is Denver's premium injection molder, serving up quality since 1977. We are committed to providing our customers with the highest level of quality and service, and we have established ourselves as a trusted partner to many of the world's leading companies. We prioritize consistent results, transparency, and meaningful collaboration to find the right solution for each situation. Call us today to see if we're the right partner for your next project.

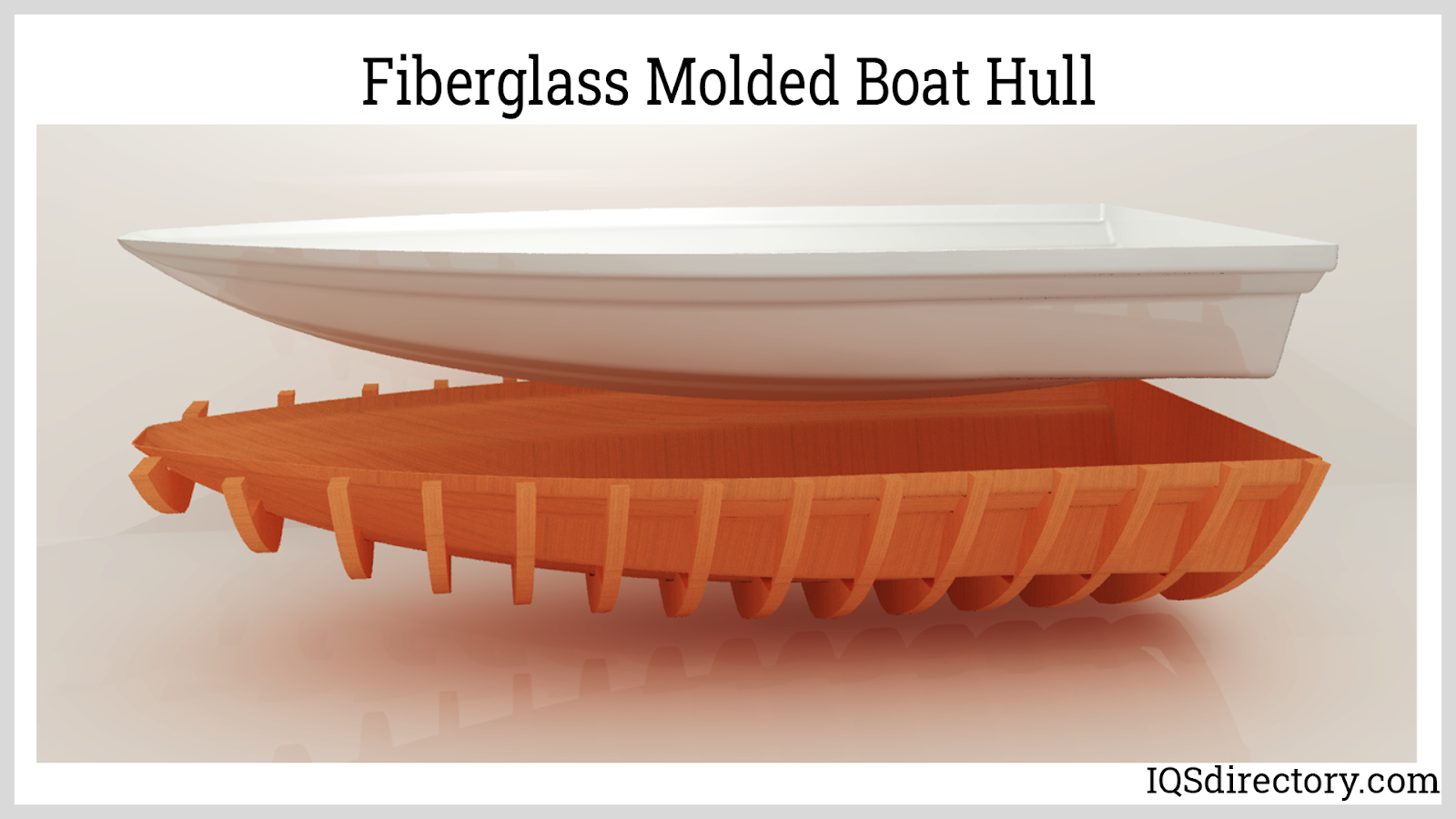

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

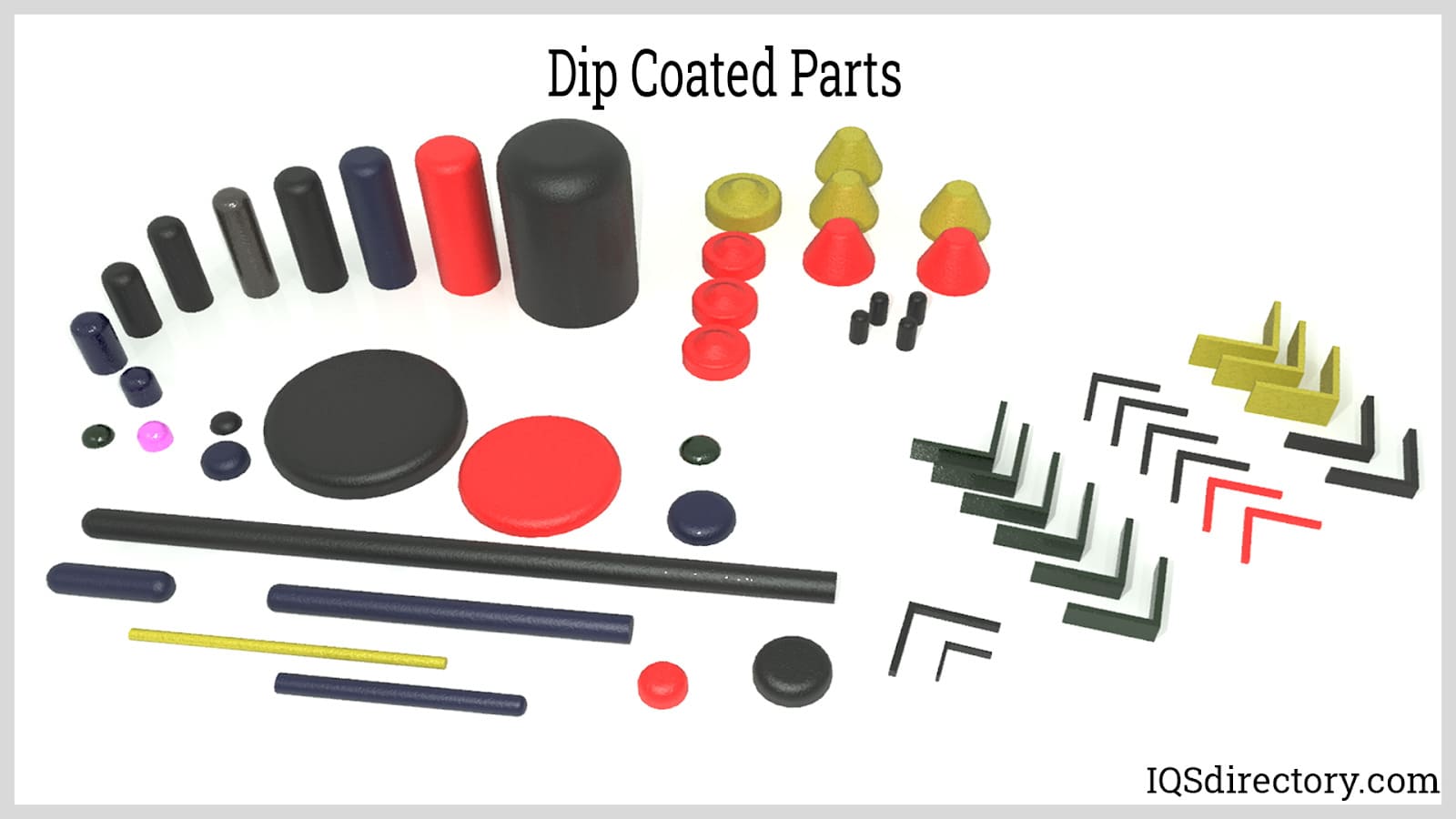

Plastic Blow Molding Plastic Dip Molding

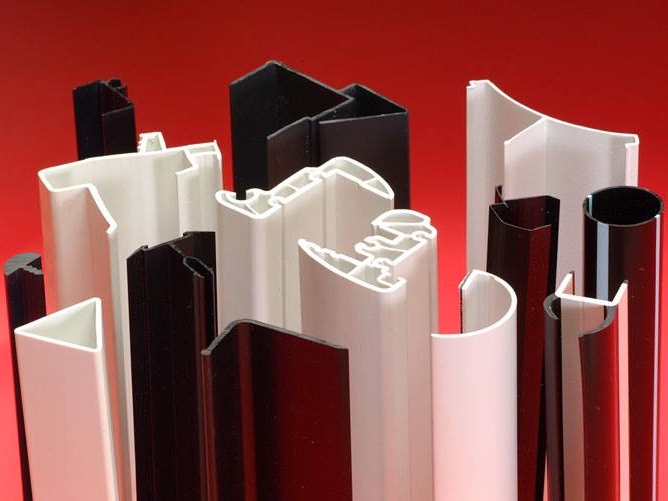

Plastic Dip Molding Plastic Extrusions

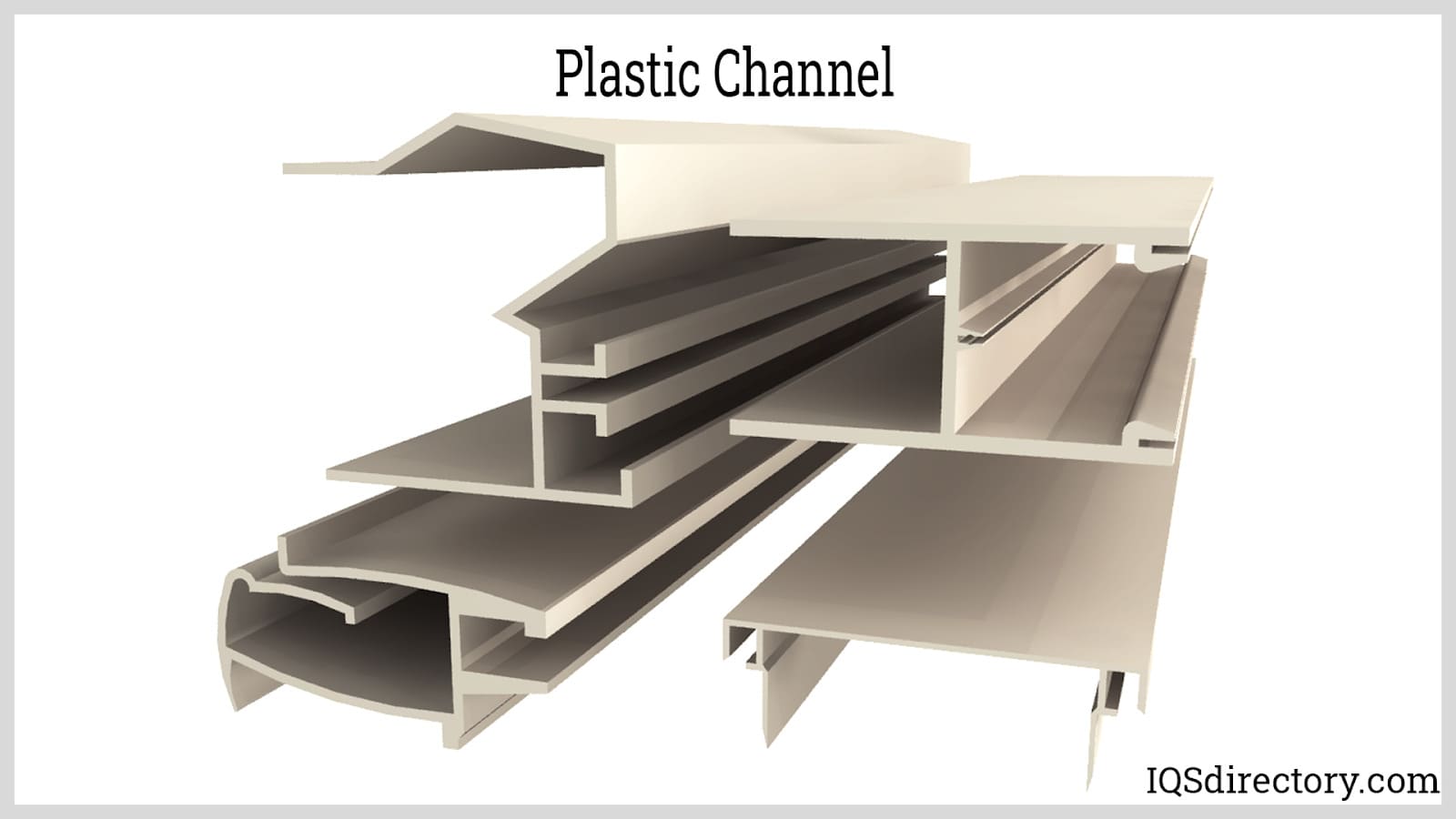

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotationally Molded Plastics

Rotationally Molded Plastics Vacuum Formed Plastics

Vacuum Formed Plastics Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services