Molded Devices, Inc.

Molded Devices, Inc.Request A Quote

Tempe, AZAt Molded Devices Inc. (MDI), we specialize in providing high-quality injection molded plastic solutions to our clients. Since 1963, we have built a reputation for excellence in the design, development, and manufacturing of plastic injection molded products. Our commitment to quality and innovation has helped us become a trusted partner for companies across a wide range of industries. Products: We offer a wide range of injection molded plastic products, including complex and simple parts, thin-walled and thick-walled parts, and large and small parts. Our products are made using a variety of materials, including engineering-grade resins, commodity resins, and specialty resins. Our products are used in a range of applications, including automotive, medical, consumer goods, and industrial applications. Services: In addition to our injection molded plastic products, we also offer a range of services to our clients. These services include design and engineering, tooling, molding, assembly, and finishing. Our experienced team of designers and engineers can work with clients to develop custom solutions that meet their specific needs. Our tooling capabilities include in-house tool design and construction, ensuring that we can deliver high-quality products on time and on budget. Capabilities: Our state-of-the-art manufacturing facilities are equipped with the latest injection molding technology, including fully automated systems, robotics, and computer-controlled machinery. This allows us to produce high-quality plastic products with consistent quality and precision. Our production capabilities include both high volume and low volume production runs, making us the perfect partner for companies of all sizes. At MDI, we are committed to delivering exceptional customer service and providing our clients with the best possible solutions for their injection molded plastic needs. We are constantly striving to improve our processes and capabilities, ensuring that we remain at the forefront of the industry. If you are looking for a trusted partner for your injection molded plastics needs, look no further than Molded Devices Inc. With our years of experience, state-of-the-art facilities, and commitment to quality, we are the perfect partner for companies across a wide range of industries. Contact us today to learn more about our products and services and how we can help you achieve your goals.

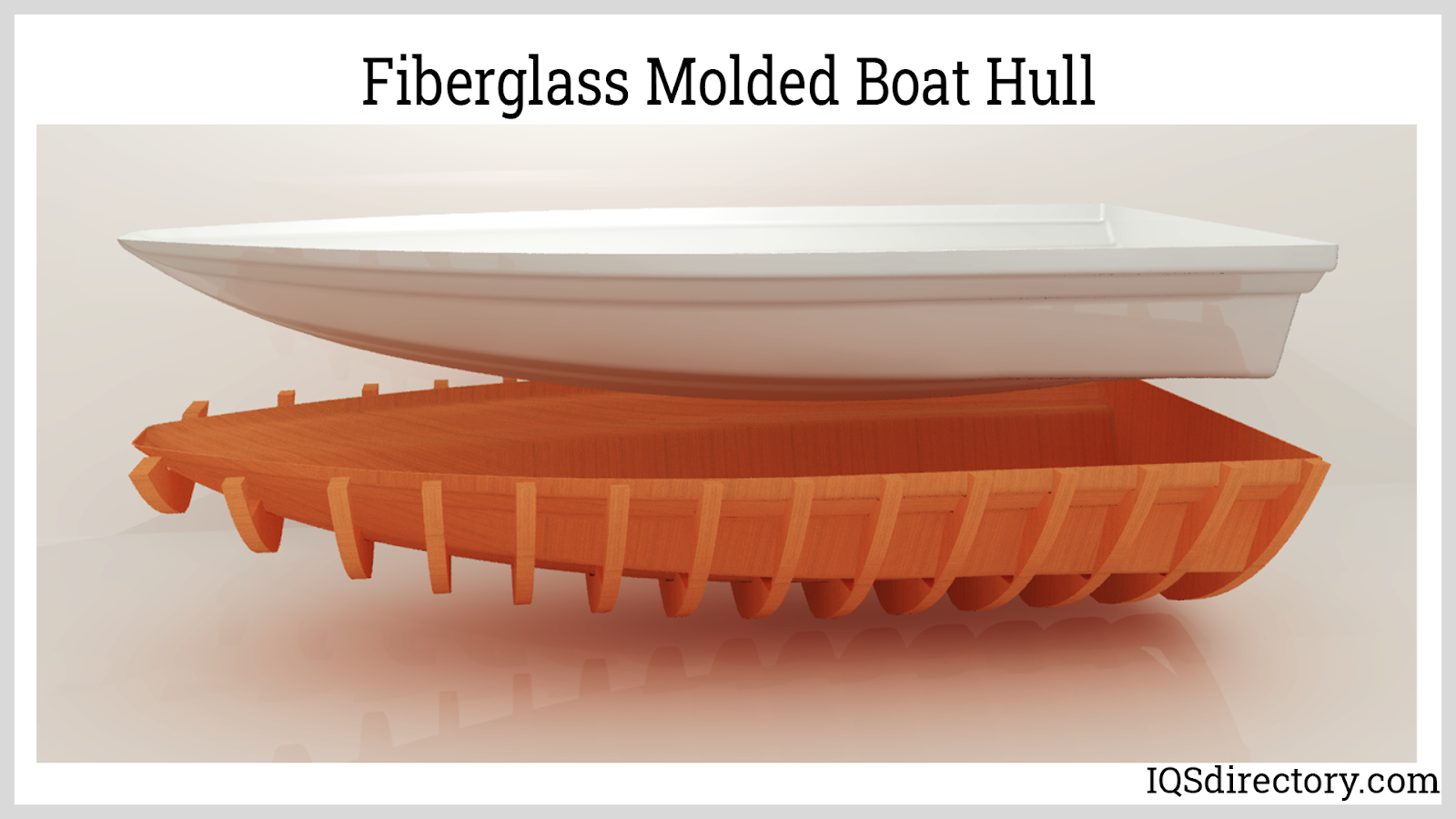

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

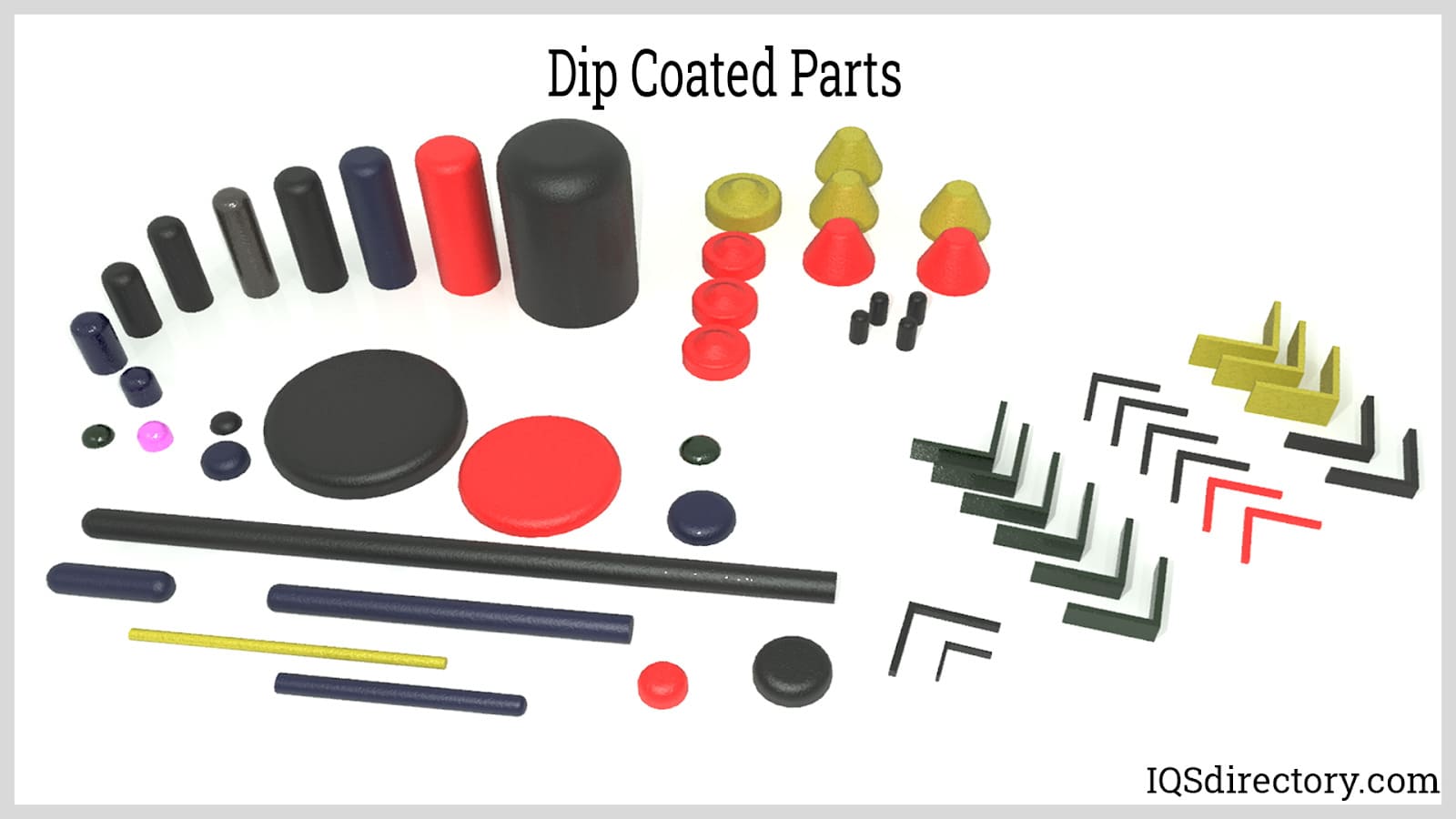

Plastic Blow Molding Plastic Dip Molding

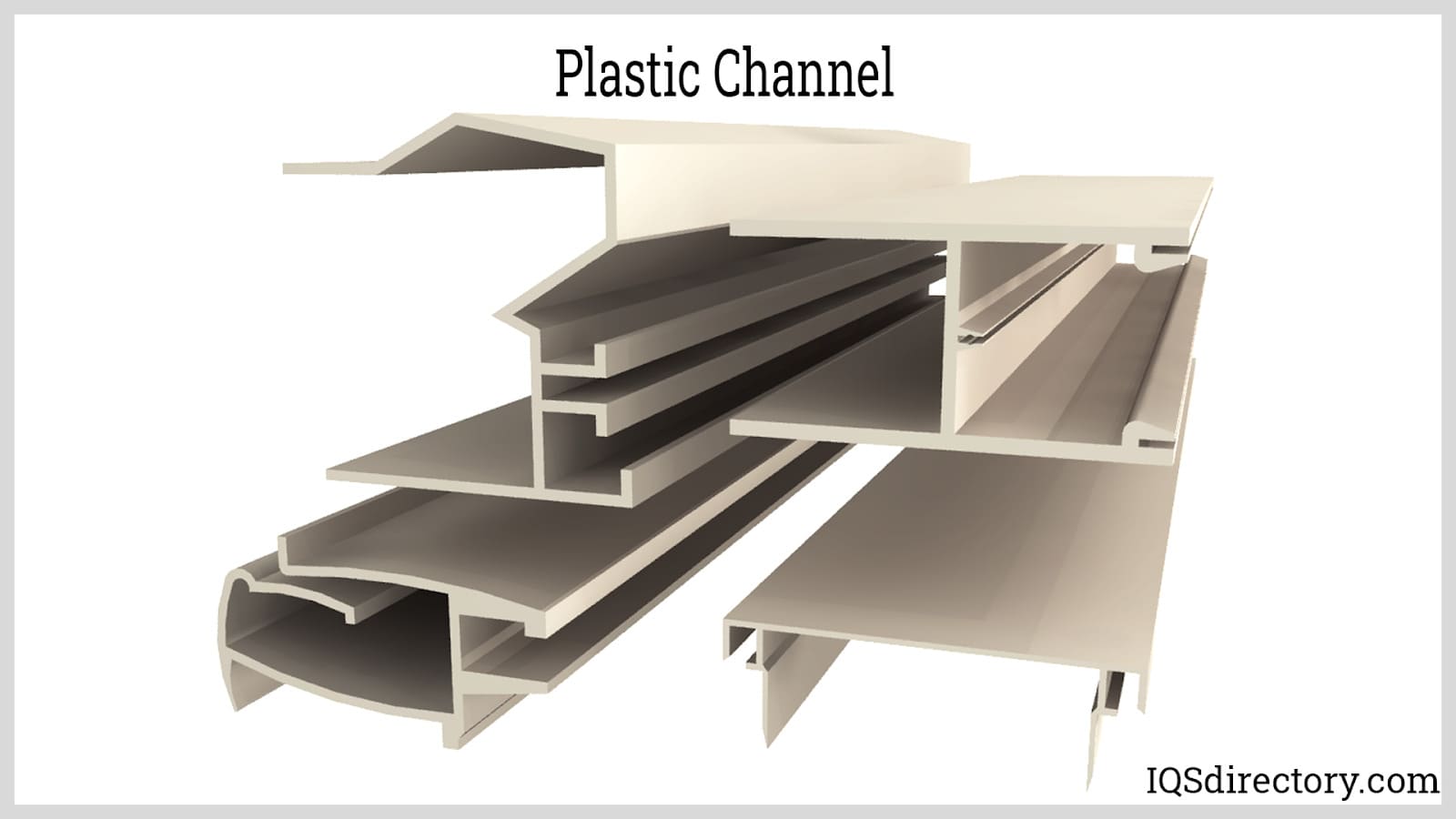

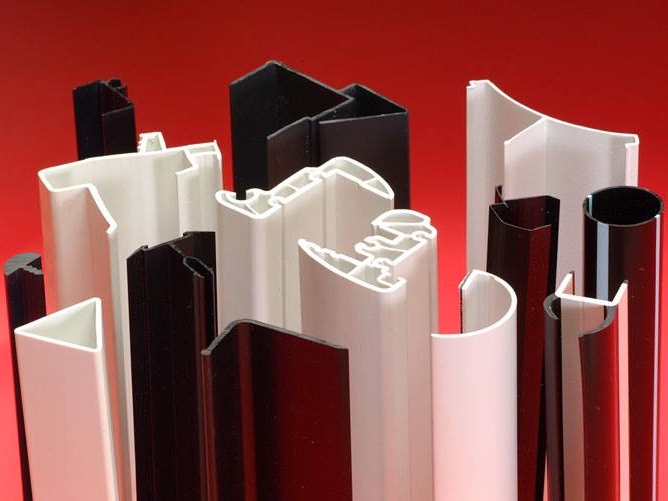

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotationally Molded Plastics

Rotationally Molded Plastics Vacuum Formed Plastics

Vacuum Formed Plastics Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services