Montville Plastics & Rubber

Montville Plastics & RubberRequest A Quote

Parkman, OHBased in Parkman, Ohio, Montville Plastics & Rubber has etched its legacy as a dynamic force since its inception in 1977. Renowned for their precision profile plastic extrusion mastery across a myriad of materials and industries, Montville Rubber and Plastics is synonymous with innovation and reliability. Their extensive capabilities are a testament to their comprehensive approach. Starting with Design & Engineering, they boast a team of adept professionals who craft visionary solutions tailored to the specific needs of clients. Tool & Mold Making is another area where Montville excels, employing cutting-edge techniques to forge molds that underpin the production of exceptional plastic components. Montville's prowess in Plastic Extrusion is a cornerstone of their identity, as they artfully craft profiles of varying complexity from diverse materials, catering to industries spanning the gamut. Their Injection Molding capabilities stand as a testament to their technical prowess. Armed with machines capable of accommodating requests up to 48 ounces and clamping forces of up to 420 tons, they offer a versatile array of molding options. Single or multiple cavity mold making, over molding, insert molding, and multiple side pulls are all within their skillset, demonstrating their commitment to adaptability and innovation. A defining hallmark of Montville Plastics & Rubber lies in their dedication to utilizing a wide spectrum of resins and additives. This meticulous selection ensures that every product or part not only meets but exceeds temperature, durability, and flexibility requirements, marking a distinct commitment to quality. Montville's dedication to value-added services further underscores their customer-centric approach. Be it fine-tuning designs, enhancing manufacturing processes, or offering invaluable insights, their commitment to going the extra mile stands as a testament to their unwavering dedication. As a beacon of innovation and expertise, Montville Plastics & Rubber remains a steadfast partner in the ever-evolving world of plastics and rubber manufacturing. Their injection molding capabilities, marked by the ability to cater to diverse requests while upholding stringent quality standards, exemplify their commitment to precision and excellence. Through decades of growth and evolution, Montville Plastics & Rubber remains a cornerstone of industry, delivering solutions that consistently surpass expectations.

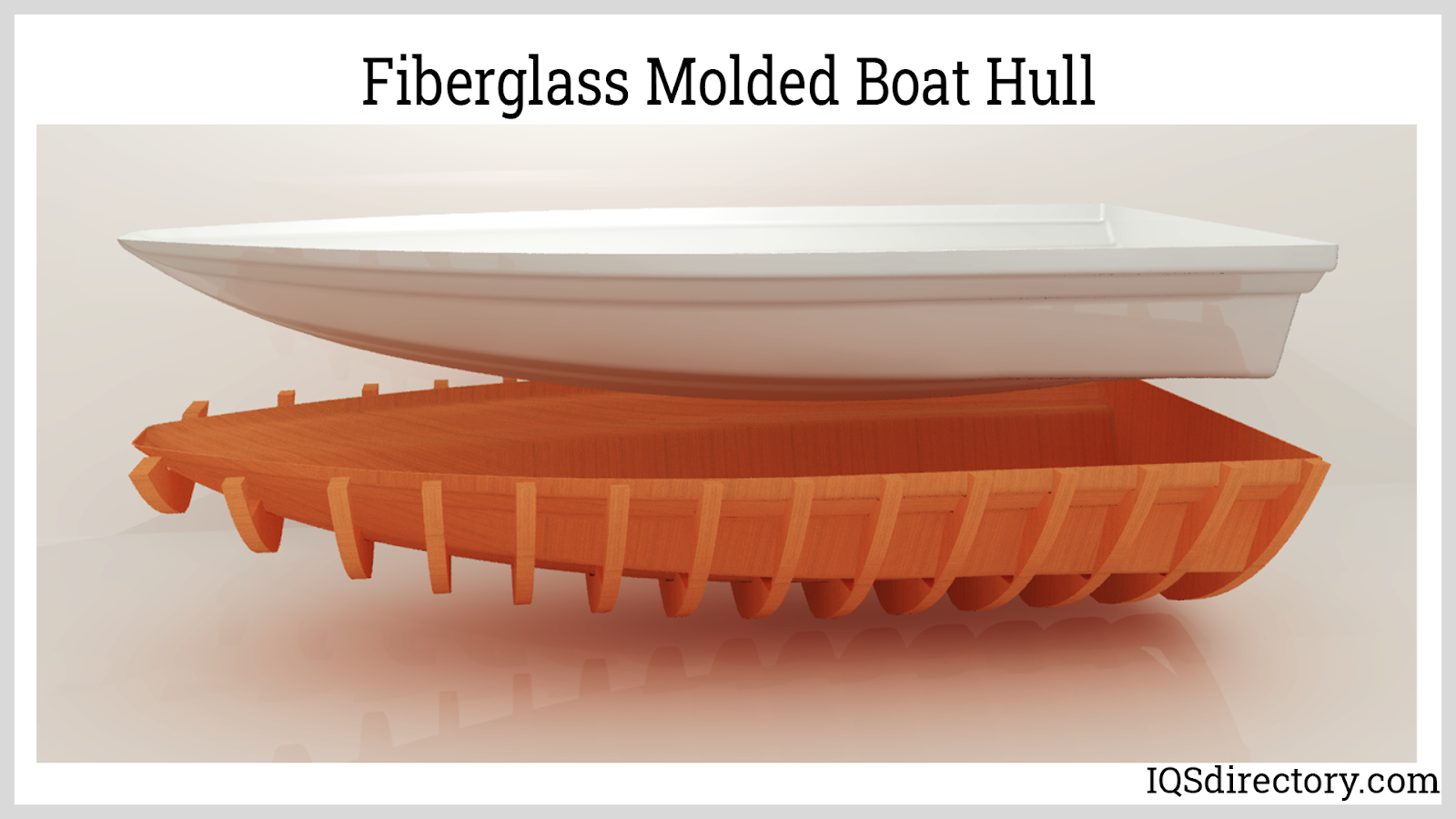

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

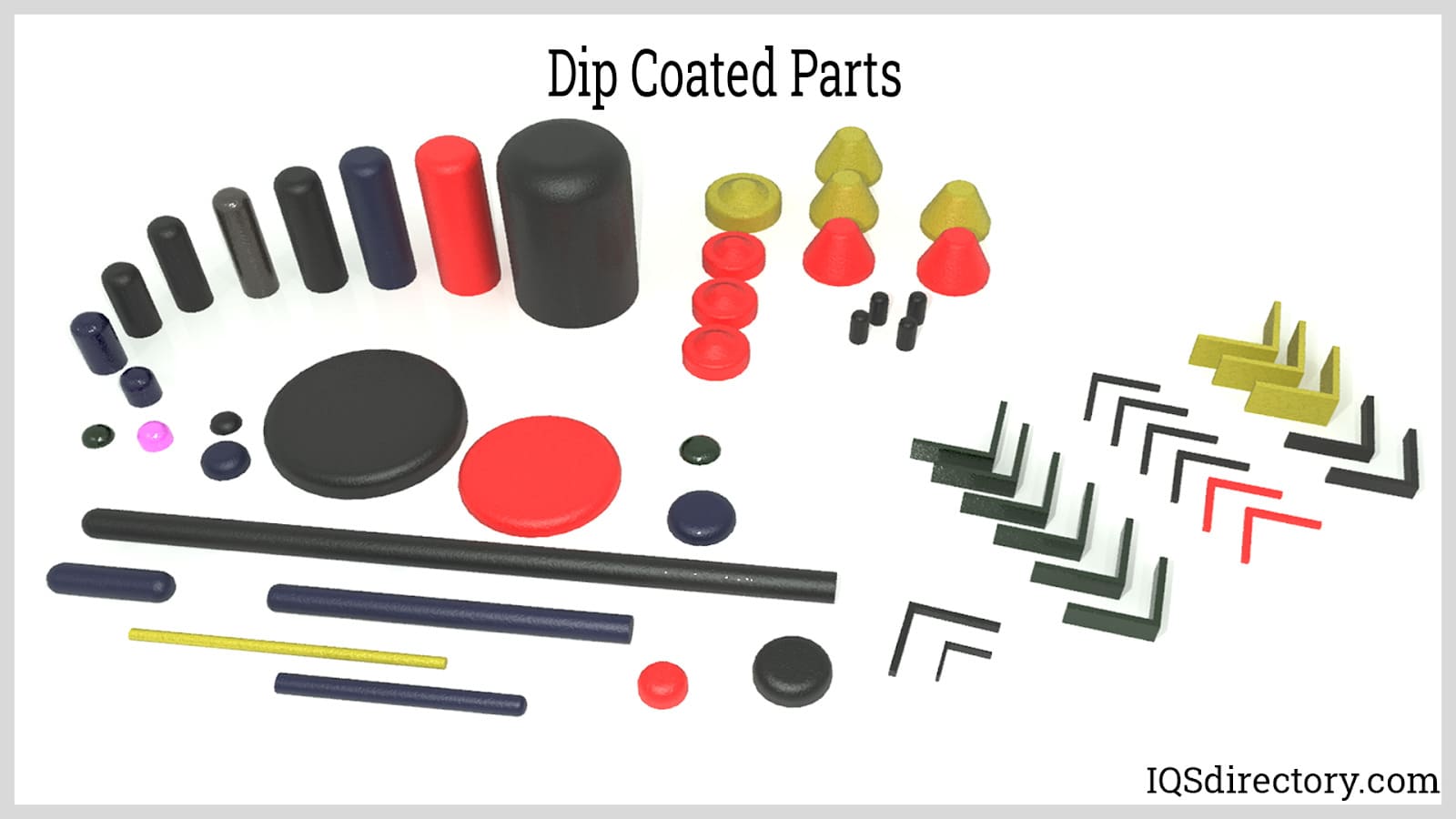

Plastic Blow Molding Plastic Dip Molding

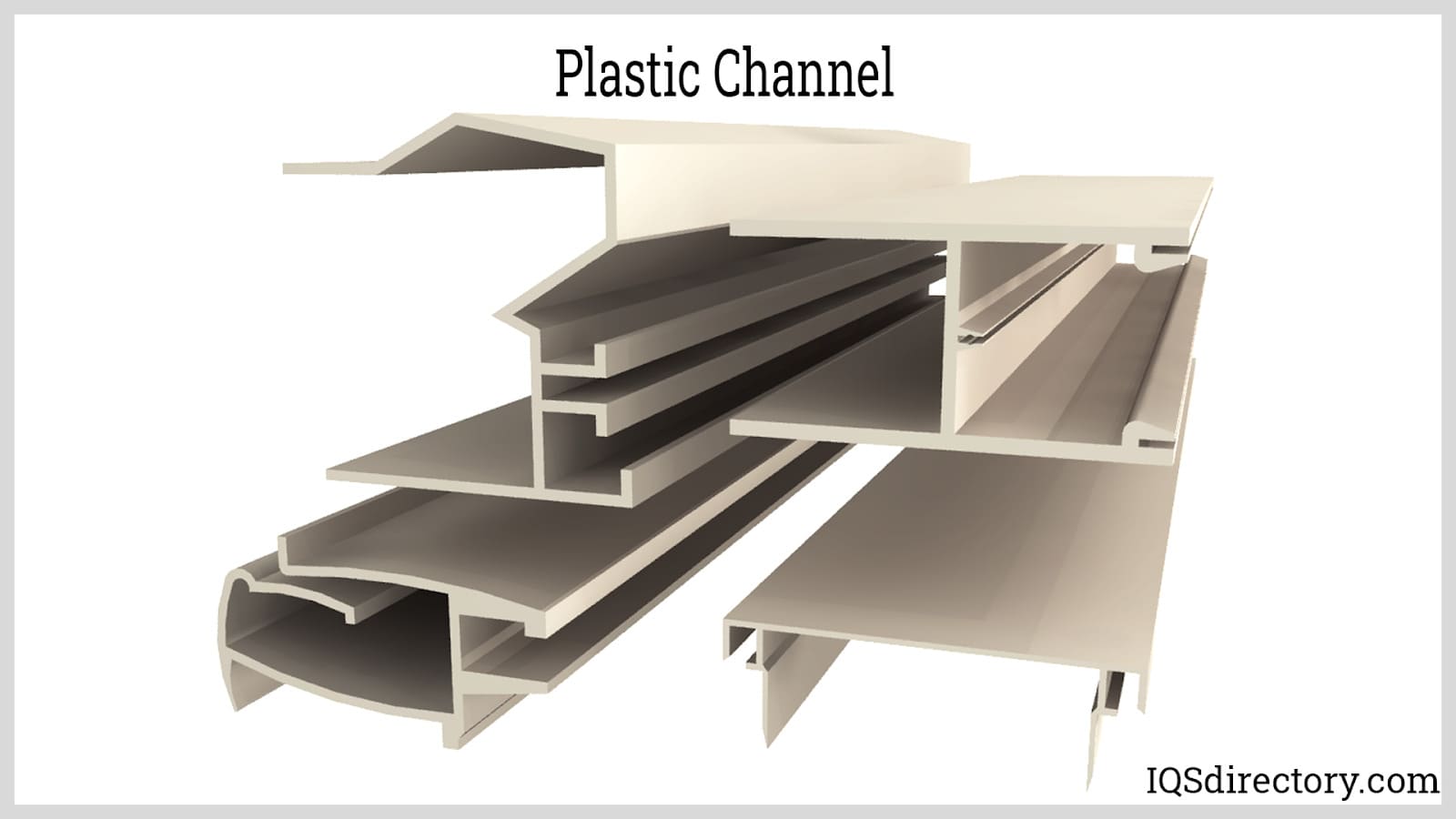

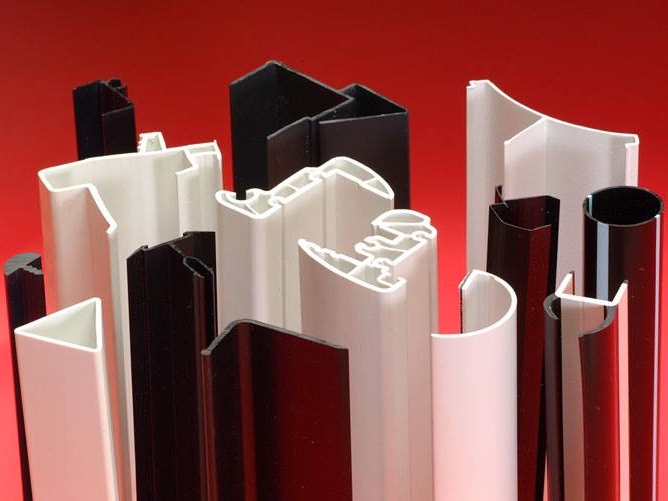

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotationally Molded Plastics

Rotationally Molded Plastics Vacuum Formed Plastics

Vacuum Formed Plastics Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services