Wisconic

WisconicRequest A Quote

Hartland, WIWe at Wisconic are pioneers in the realm of injection molded plastics. Our company stands as a testament to innovation, precision, and excellence in the industry. With a relentless dedication to quality and cutting-edge technology, we craft solutions that redefine possibilities and exceed expectations. At Wisconic, our suite of products and services is meticulously designed to cater to diverse needs across various sectors. We specialize in creating custom injection molded plastic components that serve an array of industries, including automotive, healthcare, consumer electronics, and more. Our expertise lies in producing intricate and high-performance parts that meet the stringent standards of modern applications. Our products range from intricate components for intricate medical devices to robust parts for automotive systems. We excel in crafting precision-molded housings for electronic gadgets, ensuring both functionality and aesthetics. Our portfolio extends to encompass a wide array of plastic components, each crafted with utmost attention to detail and quality. At Wisconic, our passion for innovation, commitment to quality, and dedication to customer satisfaction define us. We continuously strive to push boundaries, delivering exceptional products and services that make a tangible difference in industries worldwide.

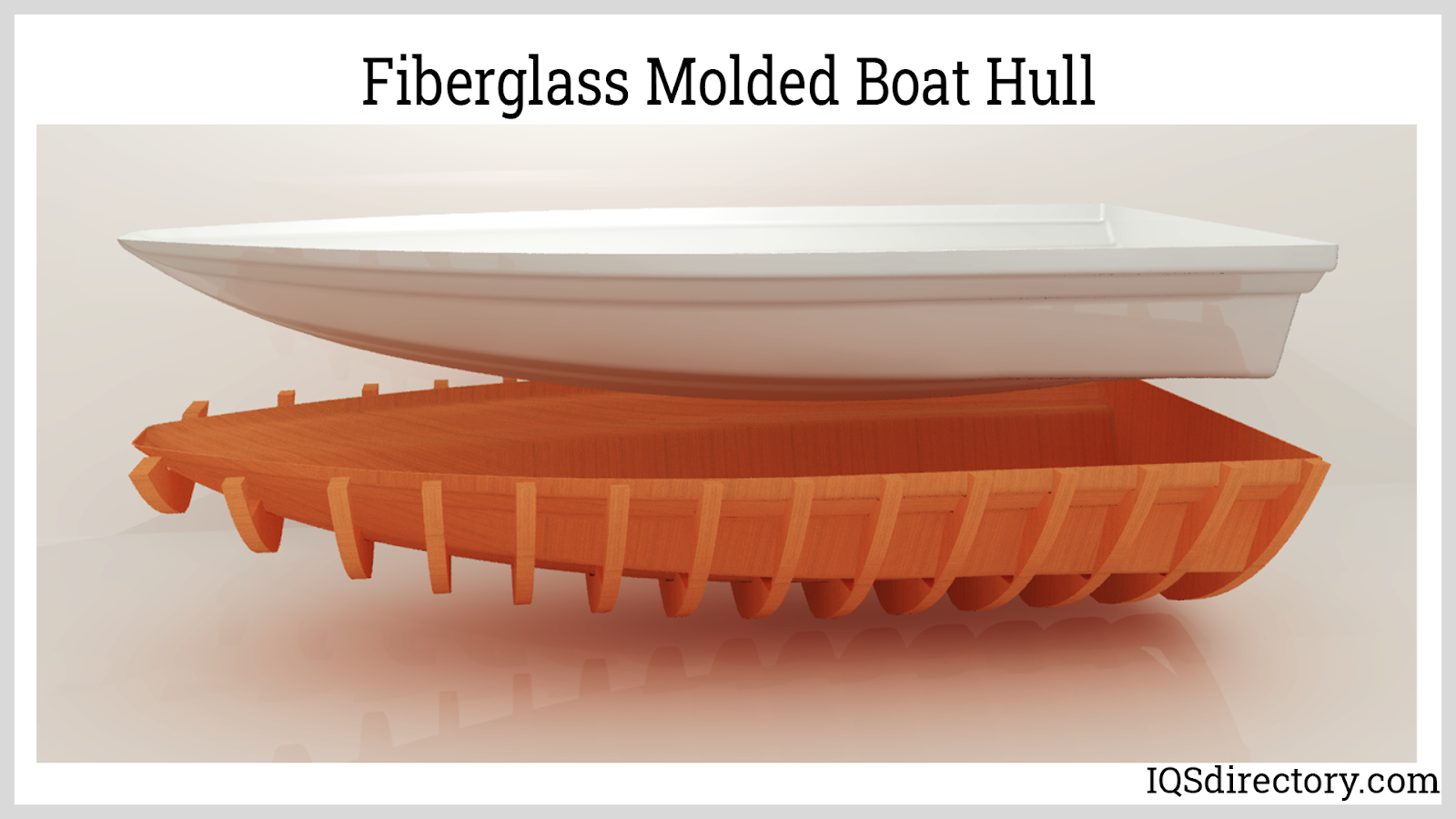

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

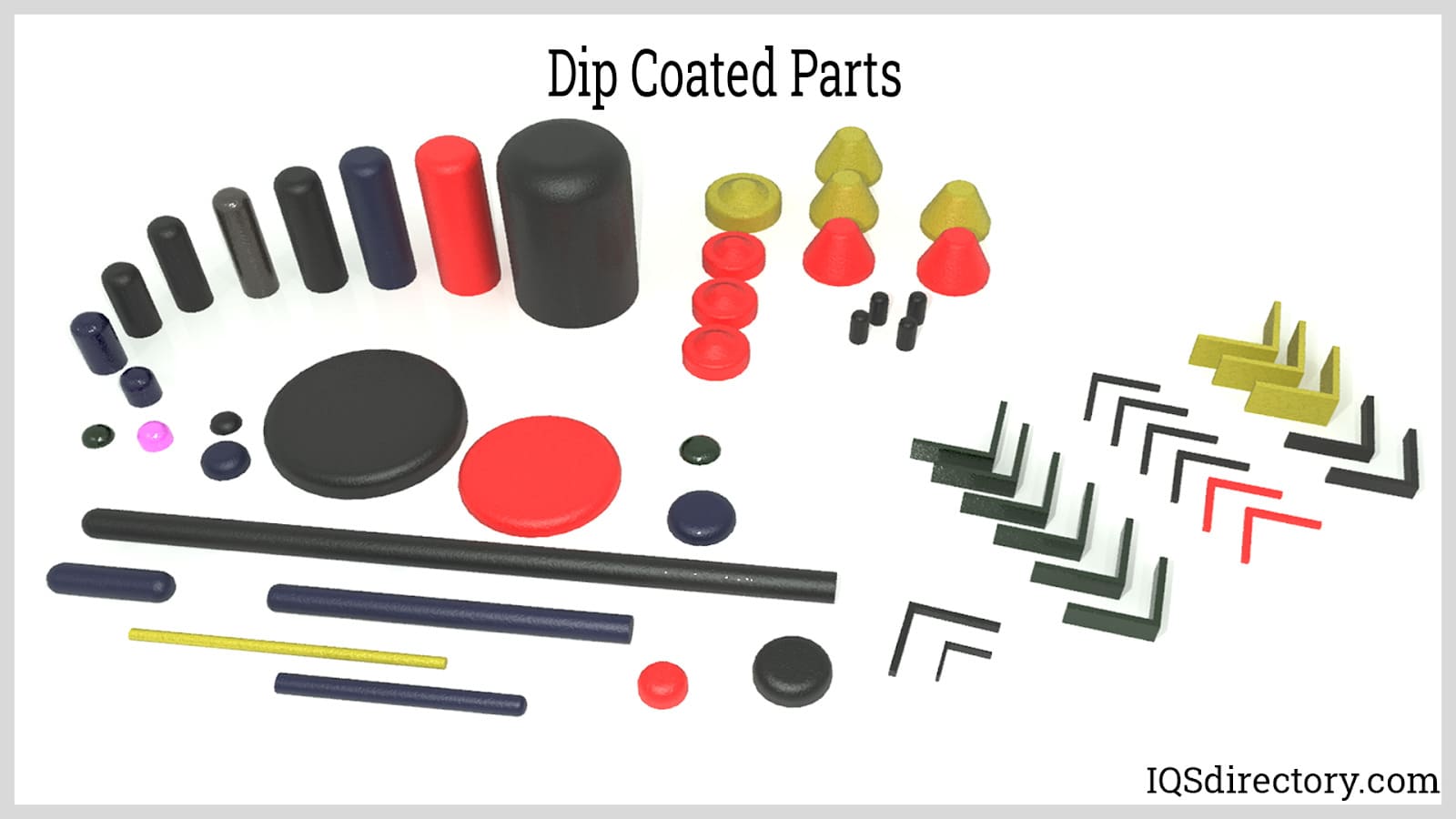

Plastic Blow Molding Plastic Dip Molding

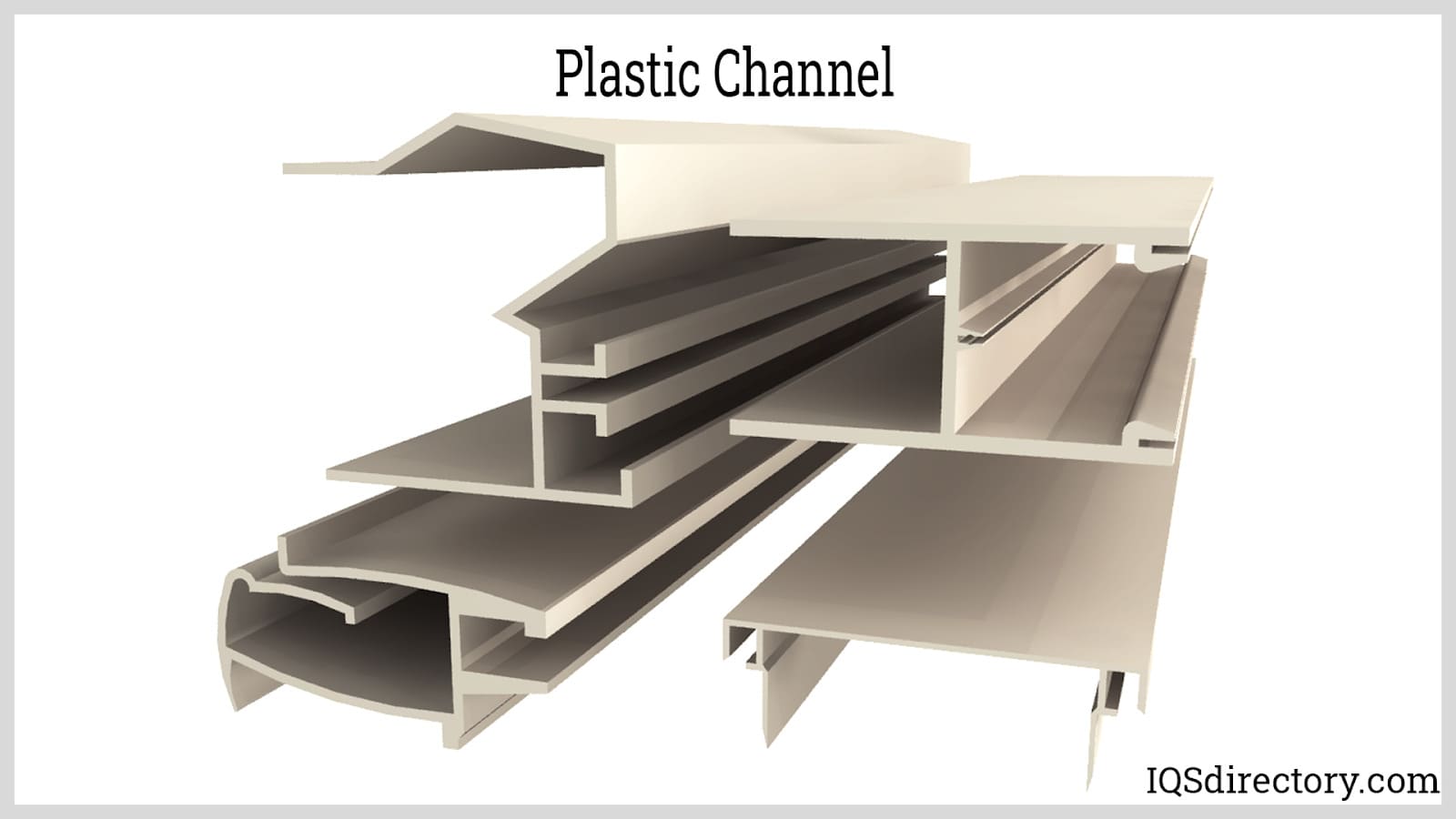

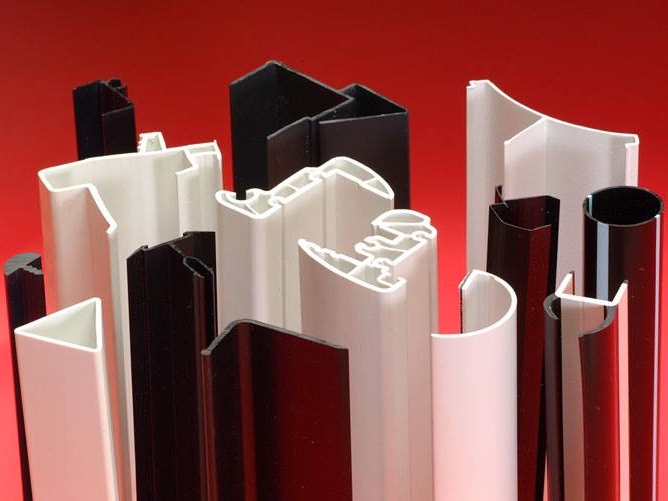

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotationally Molded Plastics

Rotationally Molded Plastics Vacuum Formed Plastics

Vacuum Formed Plastics Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services