Zero Tolerance LLC

Zero Tolerance LLCRequest A Quote

Clinton Township, MIAt Zero Tolerance LLC, we are a trusted leader in providing high-quality injection molded plastics solutions for a wide range of industries. With years of experience and a dedication to excellence, we offer comprehensive products and services tailored to meet the unique needs of our clients. Our injection molded plastics capabilities cover a diverse array of applications, including automotive, consumer goods, electronics, medical devices, and more. Using state-of-the-art equipment and advanced manufacturing techniques, we specialize in producing precision-molded parts and components with exceptional accuracy and consistency. We understand that every project has its own set of requirements and challenges. That's why we work closely with our clients to develop customized solutions that meet their specific needs. Whether it's a complex geometric shape, a tight tolerance requirement, or a high-volume production run, our team of experienced engineers and technicians has the expertise to deliver superior results. In addition to our injection molding capabilities, we offer a comprehensive range of services to support our clients throughout the entire manufacturing process. This includes design and engineering support, material selection and sourcing, prototype development, mold design and fabrication, quality control and testing, and post-molding services such as assembly, packaging, and fulfillment. We are committed to providing our clients with the highest level of quality, reliability, and customer service. Whether you're looking for a partner for prototype development, low-volume production, or high-volume manufacturing, Zero Tolerance LLC is here to help. Contact us today to learn more about how we can meet your injection molded plastics needs and help you bring your products to market with speed and efficiency.

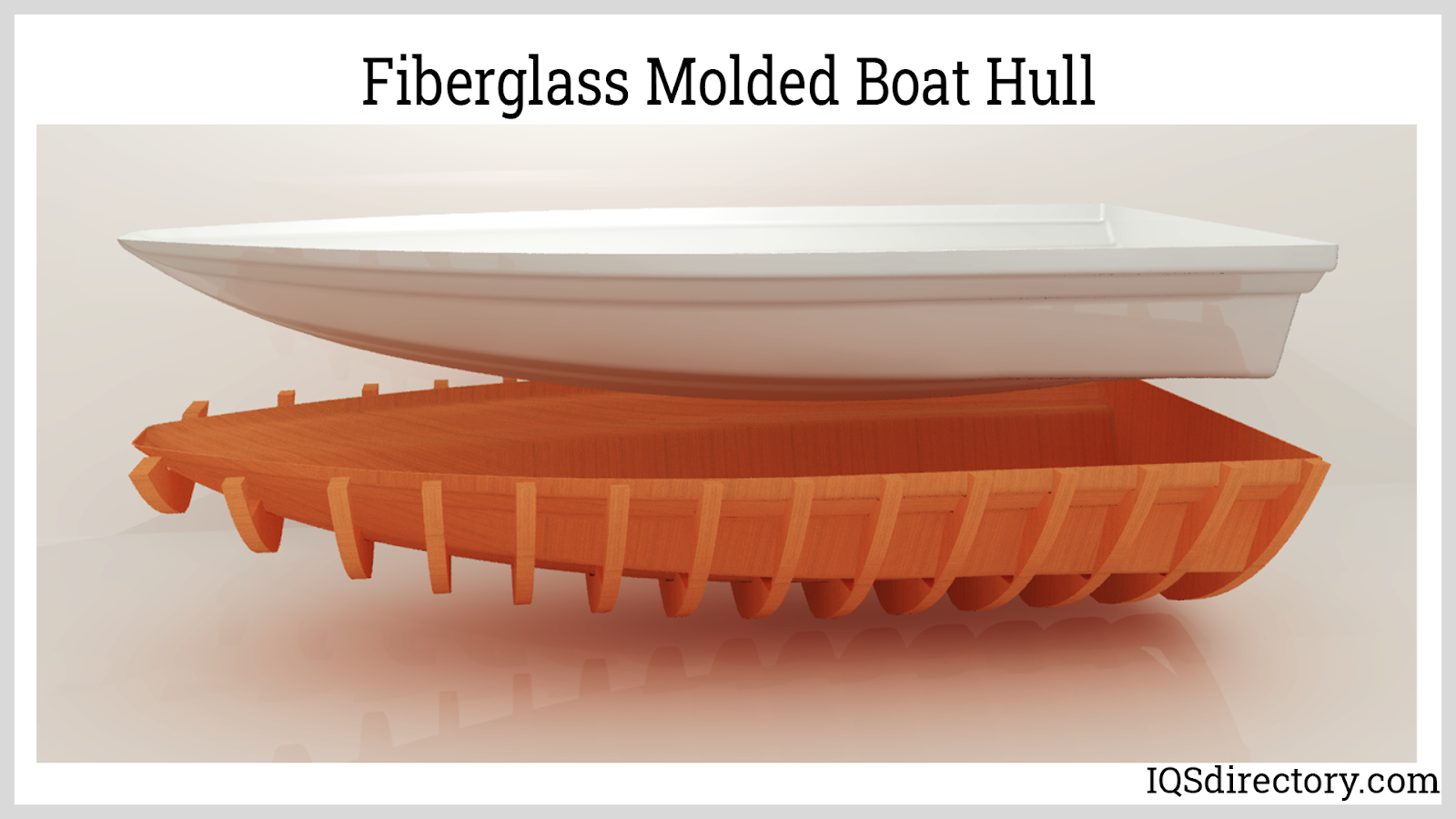

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

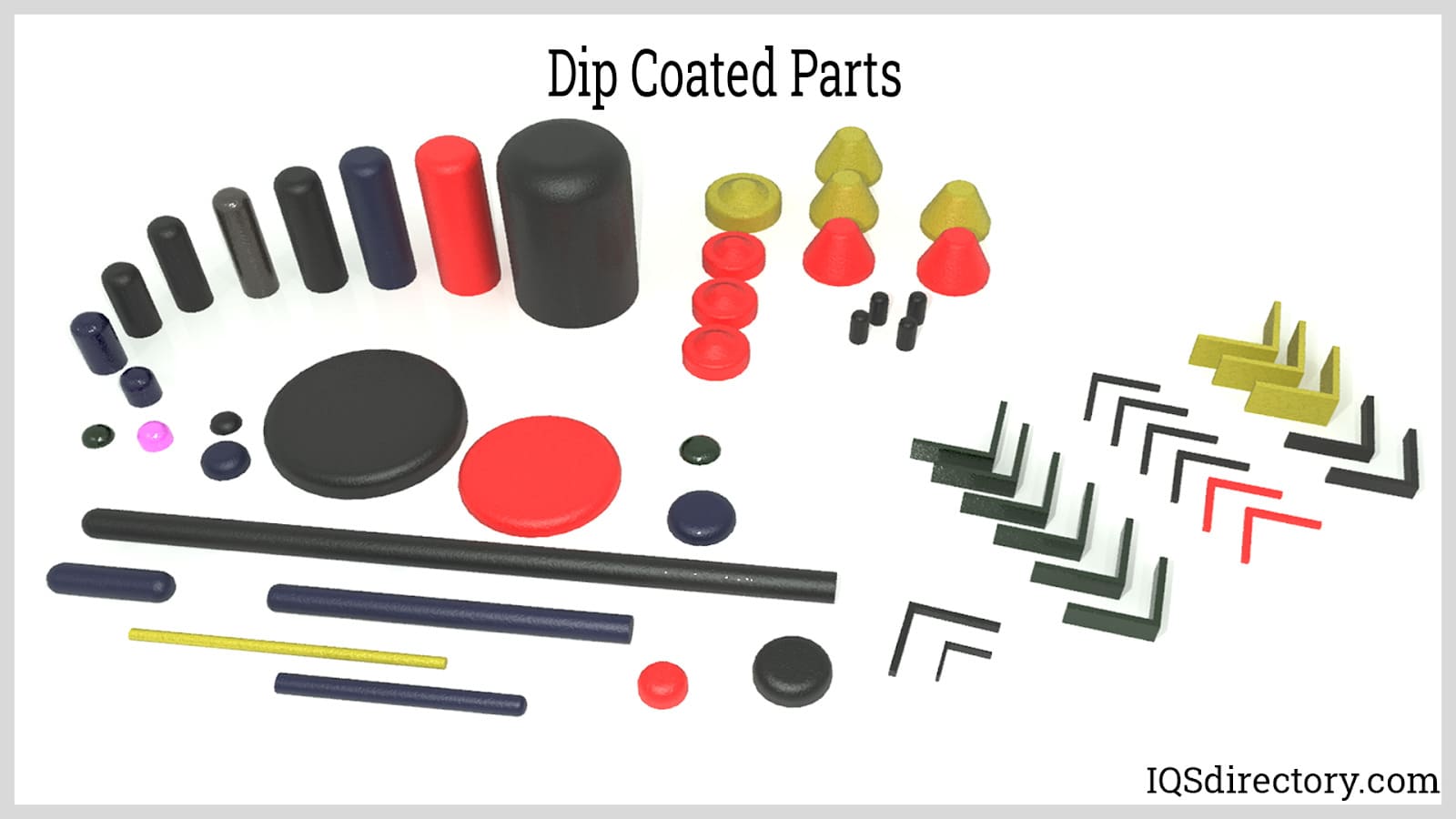

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

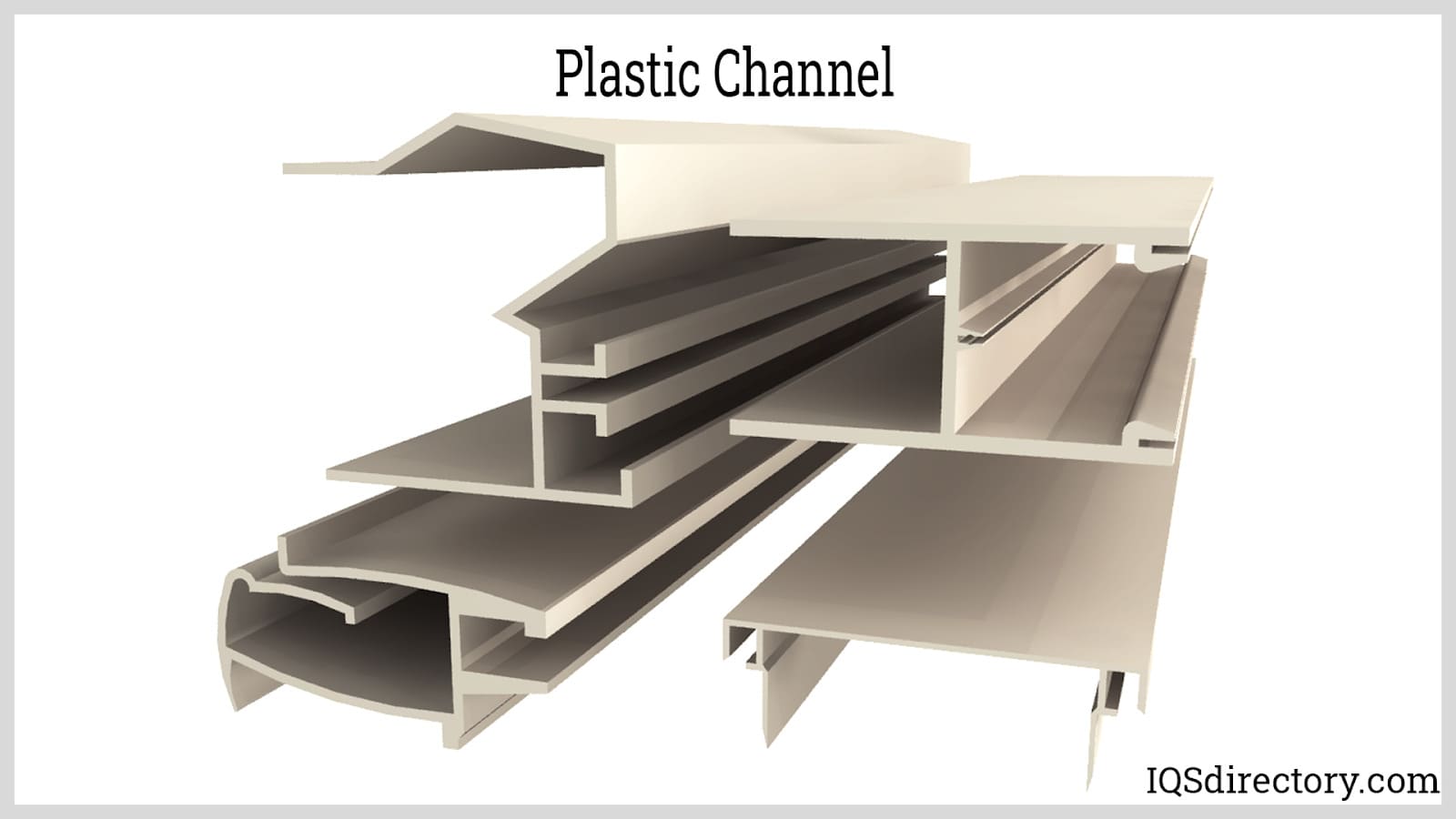

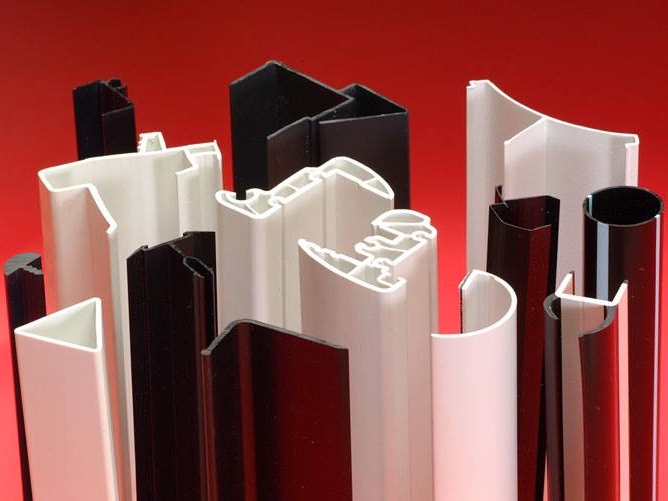

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotationally Molded Plastics

Rotationally Molded Plastics Vacuum Formed Plastics

Vacuum Formed Plastics Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services